We take you to the

NEXT LEVEL!

With Lifting Tables from LEANTECHNIK

High Speed

Tight Operating Parameters

Low Maintenance

Highest Precision

Simple Installation

Lifting tables for automotive chassis assemble are unreliable. A good example is a motionless lifting station. The chassis is delivered on a high-speed conveyor and lifts it into a stationary position. A robot pulls and installs various parts throughout the production process.

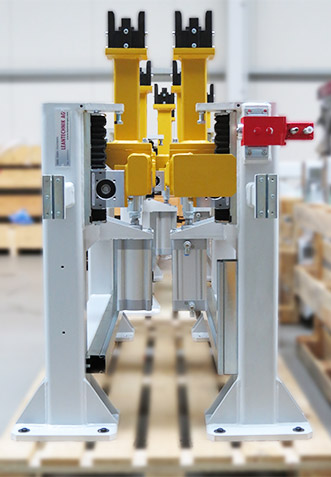

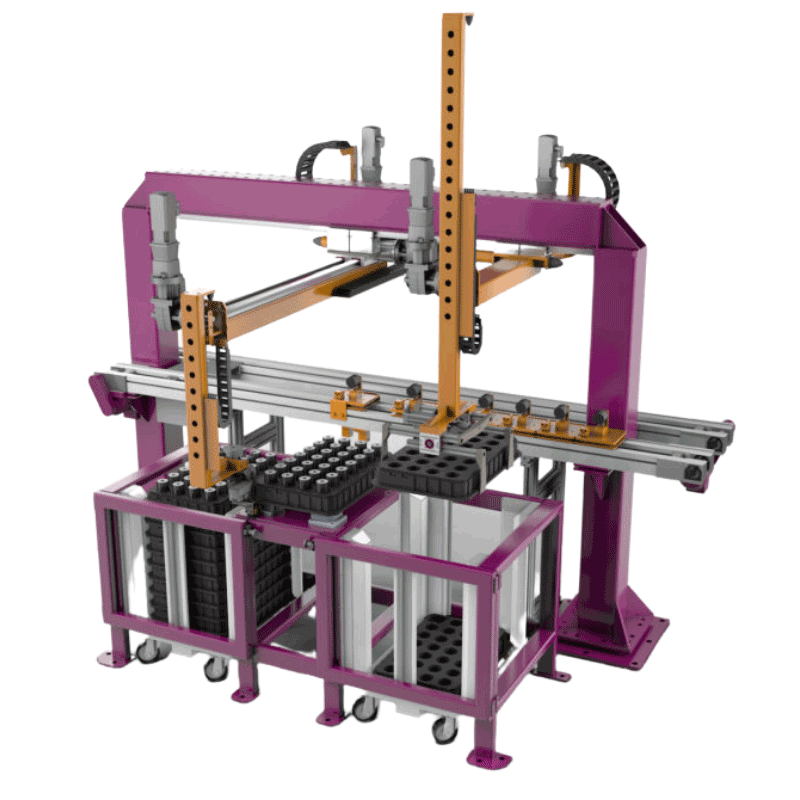

LEANTECHNIK has been a partner with the automobile industry for more than 30 years and is trusted by divisions within. High precision and efficient lifting tables / lifting systems are required, which allow robots to work at optimal levels. The lifting table pictured was built with two double lifting columns and fitted with lifgo® linear rack and pinion gearboxes. And, the vertical lift of 125 cm (49.21 inches) with the exact positioning of 0.01 mm (0.0003937 inches) is perfect to meet the high standards of the automotive industry. The double lifting table can handle high capacity loads with superb repeatability which are important factors in automotive production.

Benefit from our experienced engineering team.

They are prepared to assist with design and development recommendations of cutting-edge solutions that meet your demands and requirements.

Check out our LEANTECHNIK SYSTEMS projects and find further information in our full catalogue.

Our sales team will be happy to advise you!

Our sales staff are at your disposal at any time for a non-binding consultation at your premises. To get in touch with your contact person, take a look at who is responsible in your postcode area.

While our product development and design takes place in Oberhausen, our sales staff is at your disposal throughout the US.

Excellent customer care is part of our understanding of service.

You can find your suitable contact person below:

Inside Sales

Sales Manager (international)

ANDREAS SPRENGER

E-Mail: sprenger@leantechnik.com

Phone: +49 208 495 25 65

Mobile: +49 151 57 123 640

LEANTECHNIK SYSTEMS – Automation with a SYSTEM

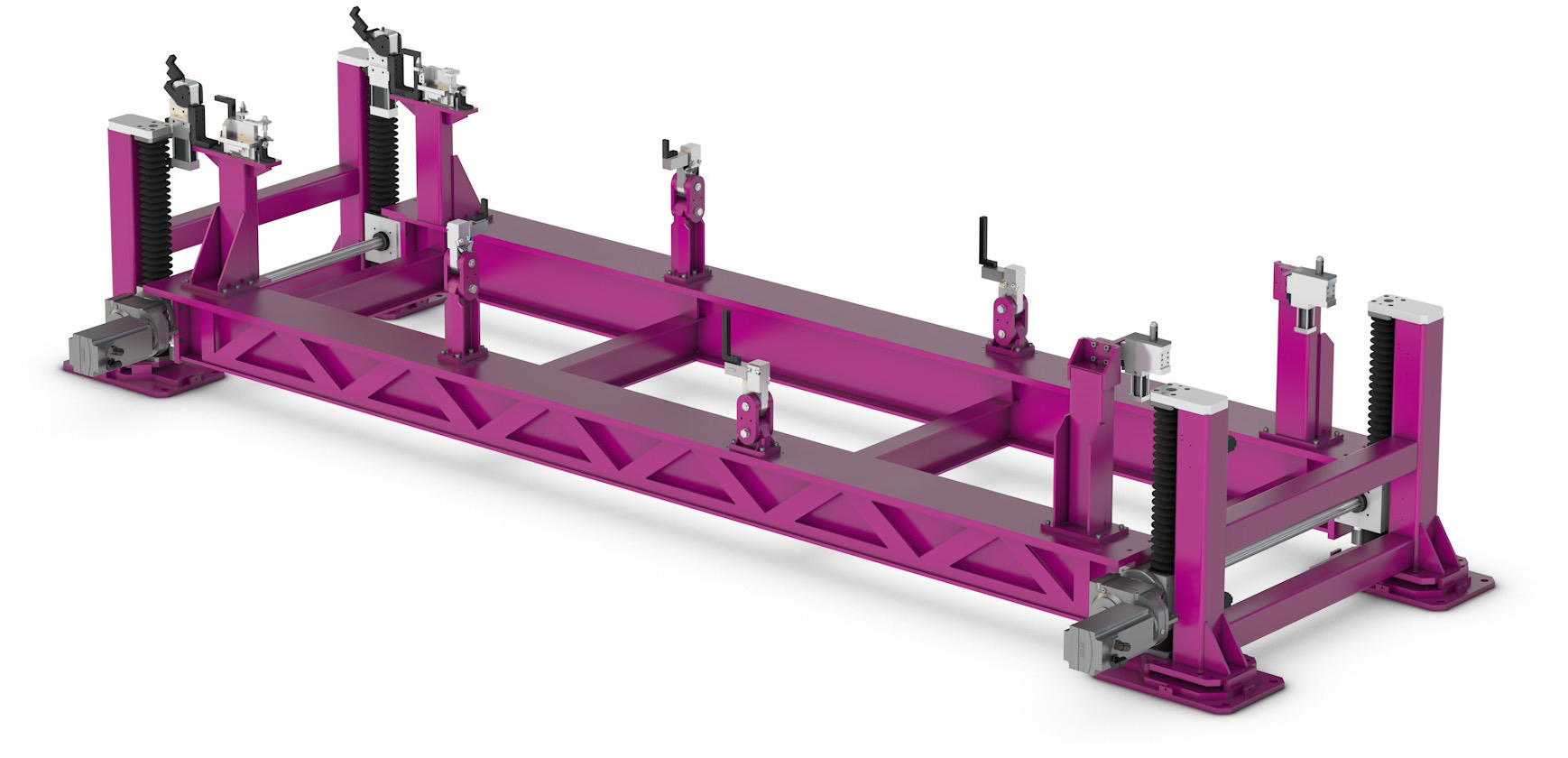

The LEANTECHNIK SYSTEMS product division refers to the development and design of partially and functionally ready plants & systems based on our lifgo® and lean SL® gearbox series.

Our motivation:

You provide the ideas – we provide the implementation!

At LEANTECHNIK SYSTEMS, we provide you with the complete know-how and implementation power of our design engineers. We accompany your project from the initial enquiry, through the complete design and planning of your system (incl. service life calculation), right up to implementation on your premises.

Discover:

Lifting Tables Lifting Columns Flexible Positioning Systems Pick & Place & more possibilities

adapted to your needs!

Benefit from the many years of experience of our team of engineers, who are on hand to advise you in the areas of development and design. LEANTECHNIK SYSTEMS stands for customised solutions that are designed especially for you, so that they are precisely tailored to your needs.