The exact solution

for your application:

Our “Lift and

Positioning SystemS”

What we offer

Multiple Choices

Selection of Parameters

Complete to your requirements

leantranspo® – Cutting Edge Solution

from the House of LEANTECHNIK

The development and construction of an individual leantranspo®-system integrates the rack and pinion gearboxes – lifgo® and lean SL®, with parts, motors and steel frame structure. Individual leantranspo®-systems can be created for the most discriminate lifting applications.

leantranspo® is significant in the development and manufacture of parts and production systems.

• Lifting Tables and Lifting Columns

• Press Transfer Lines

• Pick and Place Systems

• Two and Three Axis Portals and Positioning Systems

Benefit from our experienced engineering team. They are prepared to assist with design and development recommendations of cutting-edge solutions that meet your demands and requirements.

The system of unlimited possibilities!

The AFP®-modular system of LEANTECHNIK !

Universal accessory mounting

Extremly tight operating parameters

Freely selectable drive position

Highest precision

Simple & Quick installation

Application Alternatives

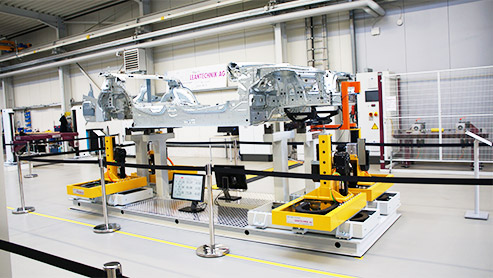

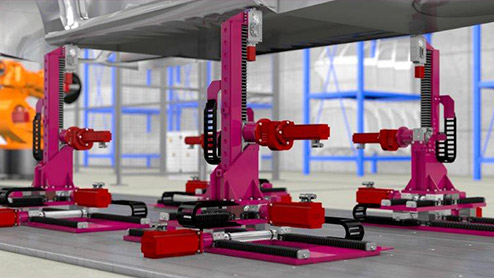

MOTIONLESS LIFTING STATION

Lifting tables for automotive chassis assemble are unreliable. A good example is a motionless lifting station. The chassis is delivered on a high-speed conveyor and lifts it into a stationary position. A robot pulls and installs various parts throughout the production process.

LEANTECHNIK has been a partner with the automobile industry for more than 25 years and is trusted by divisions within. High precision and efficient lifting tables / lifting systems are required, which allow robots to work at optimal levels. The lifting table pictured was built with two double lifting columns and fitted with lifgo® linear rack and pinion gearboxes. And, the vertical lift of 125 cm (49.21 inches) with the exact positioning of 0.01 mm (0.0003937 inches) is perfect to meet the high standards of the automotive industry. The double lifting table can handle high capacity loads with superb repeatability which are important factors in automotive production.

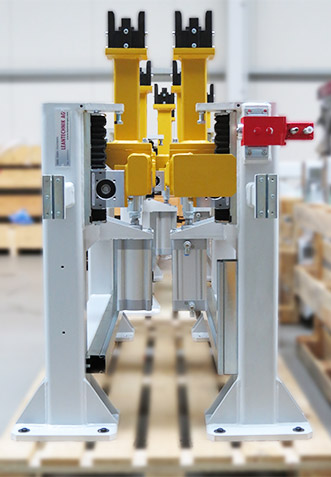

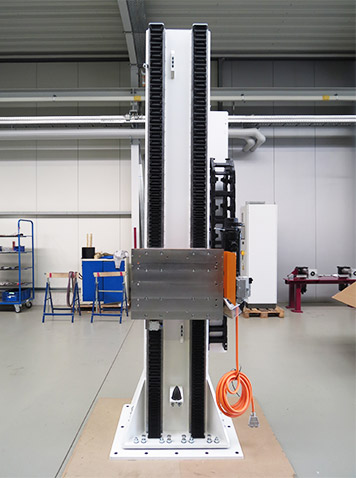

DOUBLE LIFTING COLUMN

The Double Lifting Columns from LEANTECHNIK are efficient and conserve space. Due to separate drives, the lifting devices are independent from each other so that two systems can be operated at the same time. In addition, Lifting Columns are used in the automotive industry for fabrication systems and production-line assembly. In these systems, parts such as car doors, trunk lids or hoods are produced.

In the assembly of a Lifting system, we encountered the challenges of an assembly space that had a ceiling height of only 3.2 meters (10.5 feet). Despite the limitations of the production area, our engineers were able to install the Lifting Column successfully. In 3 seconds, the Lifting System can travel up to 1800 mm (70 inches) and handle a capacity up to 850 kg (1870 lbs ). The rack and pinion gearbox, lifgo® linear 5.3 Series, each have a lifting force of 15,000 N and travel on a rack in the operational range of the Lifting Column.

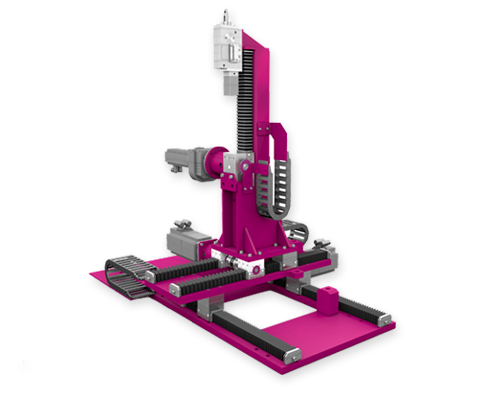

THREE AXIS POSITIONING SYSTEM (DAP)

This system was specifically developed for the automotive industry due to industry demands. All renowned automotive manufacturers are under pressure to produce a variety of models, but in smaller production runs. To meet these industry demands, production must be flexible and efficient. One option is to produce several automobile models on a production line. Consequently, you need a “Positioning System” that has been designed for such applications. Our “Three Axis Positioning System” (DAP) has the flexibility to adapt to the various types of chassis and the flexibility to transport through the production line as parts are installed.

High Precision Positioning

Primary point of DAP is our Gear Rack Drives, in that rotatory movement is transferred to linear movement. Our lifgo® Gear Rack Drives have precise roller bearings which provide exact positioning and are outstanding for high lifting speeds and the delivery of high transverse forces. There are four model variations in three sizes available and in addition the lifgo® 5.4 is for extreme weight situations.

Perfectly positioned for every automobile model.

Through the combination and synchronization of two or four lifgo® Drives powered by an electrical motor, the positioning system has the ability to move in different directions without extensive programming or assembly. Therefore, synchronized vertical and horizontal lift movements are achievable without difficulties. On the X-axis a lift from 500 mm (19.68 inches), the Y axis from 250 mm (9.84 inches) and on the Z-axis from 350 mm (13.78 inches) are possible. The repeatability lies between +/- 0.02 and +/- 0.01 mm. The lifting force is 3,500 N.

The positioning points operate independently from each other. They capture each ends of a chassis with support from take up points and are held with expanding grips. A controller jointly regulates each automobile model with essential spacing between the lifting points, lifts parts for the welding robot and manages other production processes at ideal working heights.

Flexible Engineering & Production floor planning

DAP (Three Axis Positioning) System offers the user a flexible production floorplan in which the positioning points of each chassis dimension can be automatically orientated. In this respect, LEANTECHNIK is a superior supplier in the production of multi-dimensional chassis.

For automobile assembly, we can offer our Lift & Lower Conveyor System with an additional Lifting System. It positions chassis for continuous operations with speed and precision.

leantranspo® Designed to your requirements.

- Two Axis Portals and Positioning Tables

- Two Axis Transfer & Parts Conveyor

- Three Axis Positioning Systems

- Four Axis Systems with rotating turret and Suction

- Lift & Lower Conveyor Systems

- Portal Equipment with Three Axis Grippers

- Two Axis Palletizer

- Sorting Equipments

- Lifting Columns

- Lifting Tables

With lifgo® and lean SL® we will find the suitable solution for your special application!

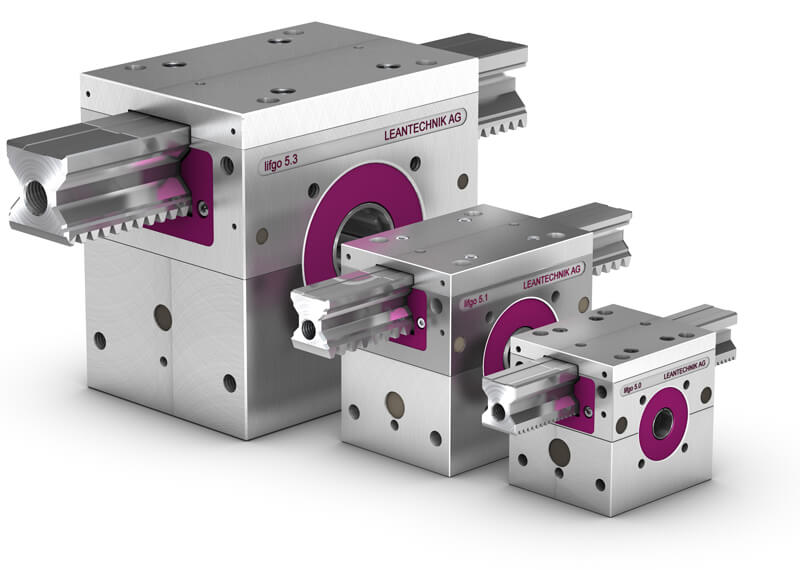

lifgo®

These rack and pinion gearboxes with linear guided racks are designed for fast, precise and synchronized systems. For applications that require high transverse forces, our lifgo® series are the first choice for capacity demands and durability.

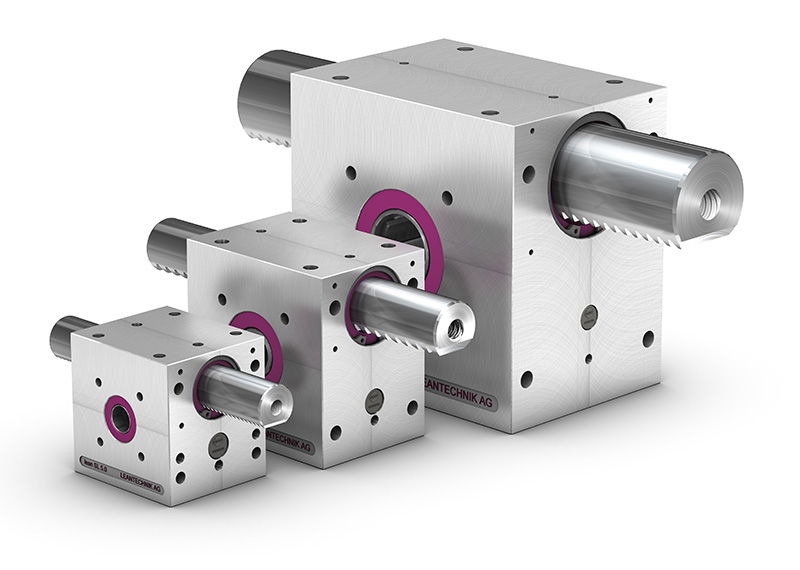

lean SL®

The robust and valuable alternative to lifgo®. This rack and pinion gearbox is designed for straightforward synchronized lifting tasks, where exact control already exists and transverse forces are not required.