Precise rack and pinion gear units enable a wide range of handling applications

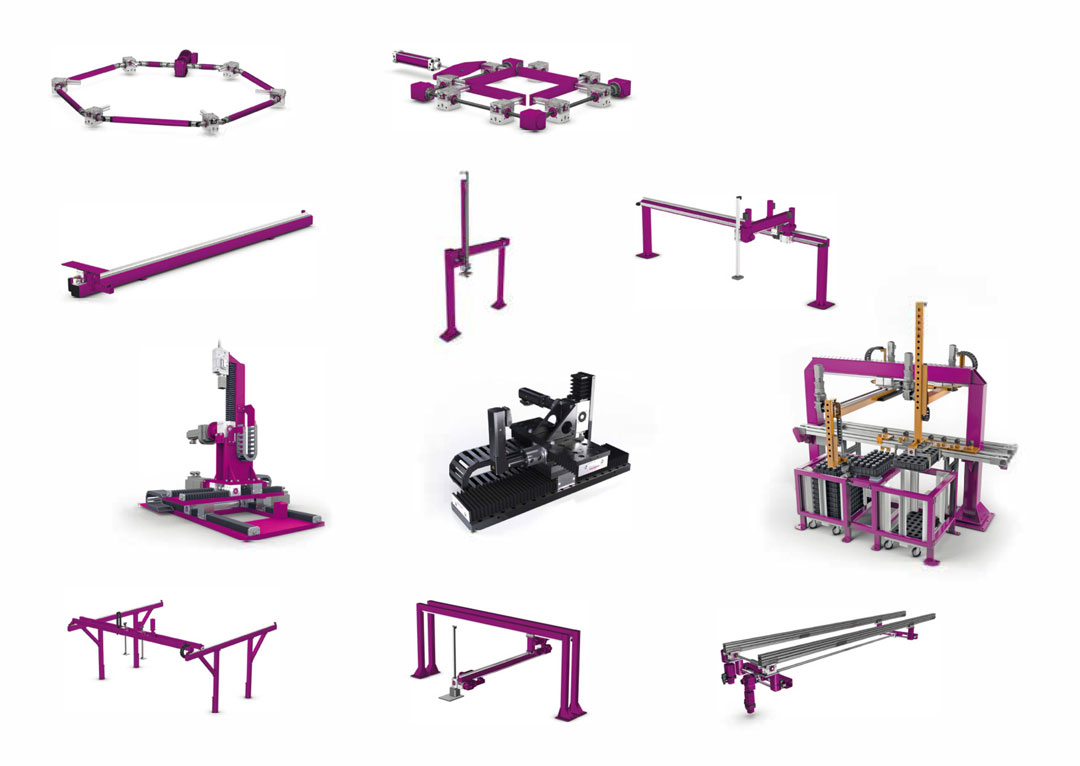

The lifgo® and lean SL® precision rack-and-pinion gear units from LEANTECHNIK can be used to solve a wide variety of synchronous positioning tasks. The modular system of the gear units enables an infinite number of combinations for applications in all industries. Based on their proven rack-and-pinion gear units, the Oberhausen-based company also manufactures customized partially and functionally ready systems.

The modular system ensures maximum flexibility in the design of handling and positioning systems. The rack and pinion gear units of the lifgo® series are particularly suitable for applications requiring high lateral force absorption or high positioning accuracy. These gear units are available in four versions, each with three sizes, and also as an eccentric version with individually adapted backlash. The lifgo® gear units are designed for lifting forces of up to 15900 N and enable a lifting speed of 3 m/s. With the lifgo® 5.4, a version has also been developed for handling particularly heavy loads, which can accommodate lifting forces of up to 25000 N.

The rack-and-pinion gear units of the lean SL® series have a round guided rack and are predestined for applications that do not require transverse force absorption and in which precise guidance is already available. These gear units are available in two versions with three sizes each, offering lifting forces between 800 and 8000 N and a lifting speed of 0.6 m/s.

Countless combination options

Thanks to the modular system, the lifgo® and lean SL® gear unit series can be combined with each other as required. Users thus have the option of designing systems of all kinds. By using several racks mounted in series, even long travel distances can be easily realized.

Based on the lifgo® and lean SL® rack-and-pinion units, LEANTECHNIK also develops customized partially and functionally ready systems. The company designs and manufactures the so-called leantranspo® systems specifically according to the customer’s specifications – this guarantees the optimum performance of the systems in daily operation. In designing the systems, the engineers make use of the special properties of rack-and-pinion gear units: The drive and guide are combined in a single unit in compact housings, and any transverse forces that occur are absorbed by the quadruple roller guide. The excellent bending stiffness of the gear units also ensures vibration-free positioning. On request, LEANTECHNIK can attach grippers, clamps, vacuum devices or other additional equipment to the ends of the racks. leantranspo® systems are used, for example, in transport technology, plant and mechanical engineering, or in the food and chemical industries.