CRASH RISK AVERTED.

Safety systems from LEANTECHNIK hold plant components firmly in position.

Gravity-loaded axes must be secured against unintentional dropping or falling. The Stepless Holding Brake (SHB) and the Mechanical Arrest System (ASS) from LEANTECHNIK are ideal for this task. They have been specially developed for use with the proven lifgo® and leanSL® rack drives.

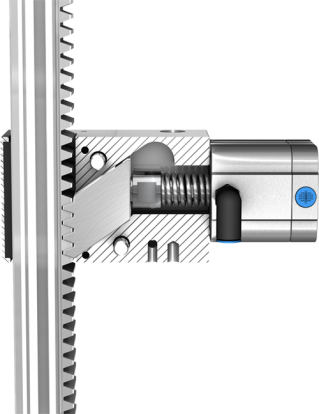

The Mechanical Arrest System (ASS) is used to lock systems and devices in case of repair or on the occasion of an inspection. It can also be used as a positioning unit for a fixed value in conjunction with a lifgo® or lean SL® gear unit.

The heart of the ASS is an air cylinder that keeps the safety device open against a spring pressure during normal operation. In case of operation, the cylinder is vented, the toothed lock moves forward towards the rack by means of spring pressure, and the system is lowered at creep speed until the toothed lock is fully lowered into the rack. After a second inductive switch has signaled to the control system that the locking position has been reached, the lowering movement is stopped immediately.

The locking device can be mounted on both lifgo® and lean SL® rack drives from LEANTECHNIK. It functions according to the principle of positive locking and can also be easily retrofitted to the gear unit. LEANTECHNIK supplies the ASS in four sizes, whereby the load restraint always corresponds to 5 times the nominal load of the respective lifgo®/lean SL® gear unit.

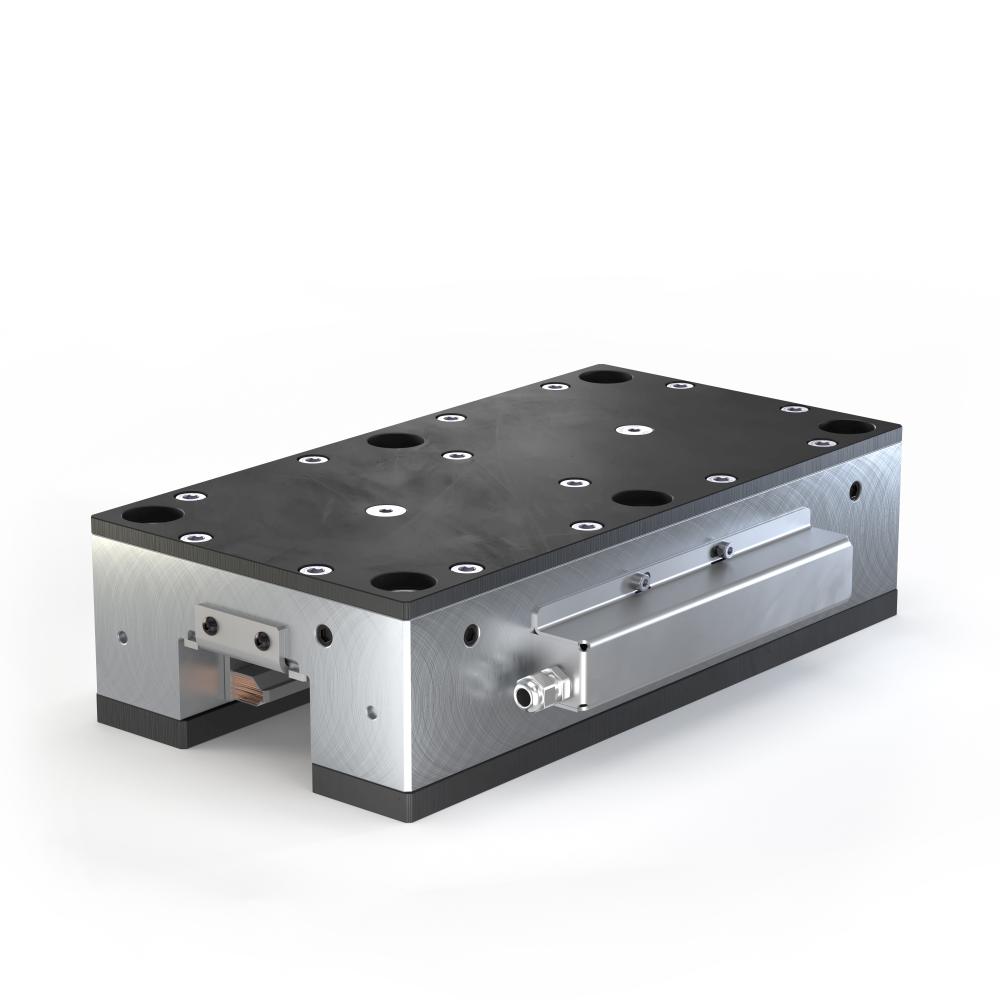

The stepless holding brake (SHB), on the other hand, can be used to secure systems and system parts against sudden lowering even during operation. The SHB also operates pneumatically and was specially designed for use on lifgo® rack-and-pinion drives. By venting the brake with the required operating pressure, the clamping element of the brake is released. Venting causes the disk spring to press on the clamping element – the profile rail is clamped.

In contrast to the ASS, the SHB has a non-positive operating principle. It can also be used as a safety brake due to the Fail Safe principle.

The SHB is available in a 6 and a 20 bar version as well as in three sizes and is supplied assembled ready for installation.

Notice:

The use of the holding brake should already be taken into account when planning the system, as retrofitting involves more effort.