The system of unlimited possibilities!

The AFP®-modular system of LEANTECHNIK !

Universal accessory mounting

Extremly tight operating parameters

Freely selectable drive position

Highest precision

Simple & Quick installation

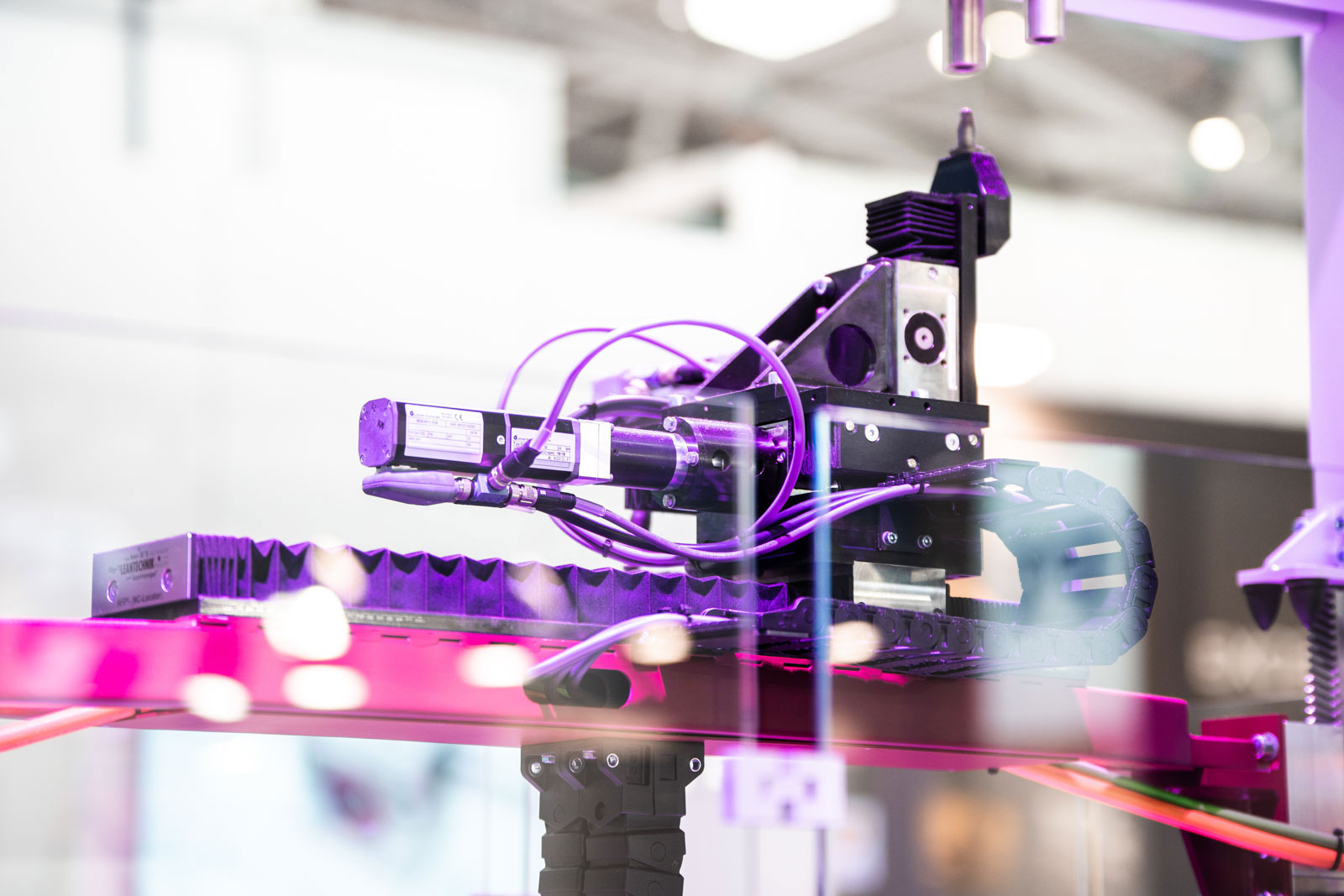

See our AFP® – modular system in action!

Highly flexible and extremly powerful:

AFP® – Actuator Flexible Position

NC-Locators enable flexible production of several product variations economically on one line.

For numerous industrial manufacturers, production costs continue to rise due to increasing number of product classifications and declining lot sizes. With the new AFP – Axis’s from Leantechnik, there is a break through from this vicious cycle; offering the opportunity to produce numerous product variations economically on one line.

The NC locators are used to position brackets, clamps, or to centralize, as well as the flexible incorporation of product components. The AFP System consists of an X axis, Y axis and a Z axis; each with a 24 V brushless DC Servo drive that contains an easily integrated programmable control and a CANBUS interface. Each axis and motor drive are defined according to the specifications of the customer and are combined according to the requirements of the application.

The system was developed on behalf of a distinguished automotive manufacturer that wanted to reorganize the fabrication of its chassis within the assembly process. A single production line ought to have the ability to produce different automotive models without having to rebuild the production line each time. To optimally meet these conditions, Leantechnik has conceptually designed the NC-Locator modules as a “System Assembly Kit”. It is composed of individual axis’s, motor drives and connectors, which can be assembled collectively to achieve designated parameters. This creates a completely individual positioning system that incorporates flexibility for changing production conditions.

Each axis and every motor drive are defined separately and combined according to the customer’s assembly specifications.

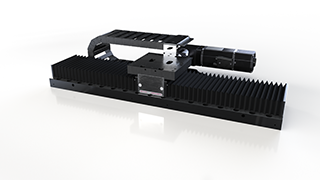

As the basis of the AFP®/NC Locators, we apply our proven lifgo® linear 5.0 Gear Rack Drives.

The transfer of rotary forces into linear motion, provides a lifting force of 2,000 newtons with a lifting speed of 3 m/s and an acceleration of 50 m/s².

The lifgo® linear series is characterized by its precise synchronization, even at high speeds and was specially designed for applications with long traverses.

The AFP® – modular system of LEANTECHNIK consists of:

X-Axis

(Longitudinal Axis)

Y-Axis

(Lateral Axis)

Z-Axis

(Lifting Axis)

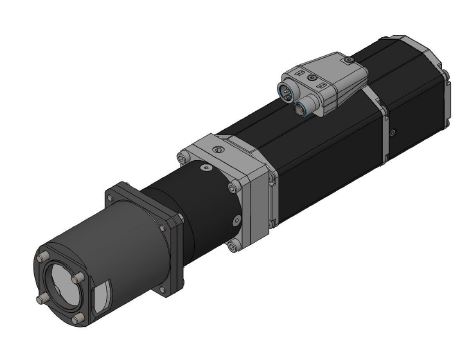

+ Drive unit

In the modular system, the axes can be combined and used individually:

One-Axis-System

Two-Axis-System

Three-Axis-System

Strokes in our AFP® – modular system

X-Axis

60 mm

150 mm

300 mm

400 mm

Y-Axis

60 mm

90 mm

180mm

Z-Axis

60 mm

90 mm

The X-Axes (longitudinal axes) are also available in the versions: “light” und “single“

In the “light”-variant with the stroke paths: 60 mm, 150 mm, 300 mm, 400 mm

In the “single”-variant with the stroke paths: 150 mm, 300 mm

More information can be found in our Technical Data.

Lifting speed of the drive units in the AFP® – modular system

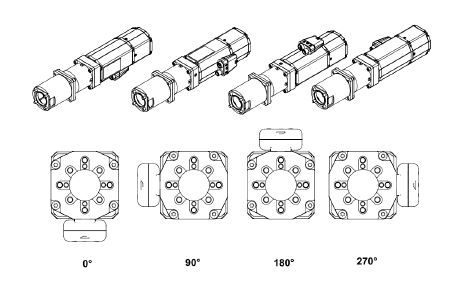

Drive unit straight

35 mm/s

90 mm/s

Connector position 0°, 90°, 180° or 270°

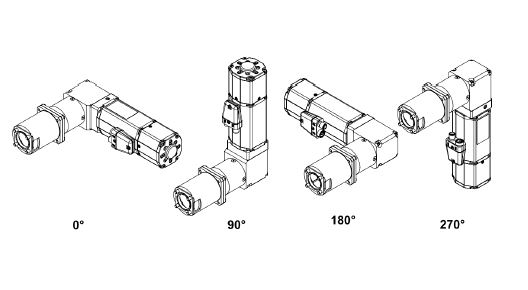

Drive unit angle

35 mm/s

90 mm/s

Mounting position 0°, 90°, 180° or 270°

You need more technical data for our AFP® - modular system?

Benefit from our experienced engineering team.

They are prepared to assist with design and development recommendations of cutting-edge solutions that meet your demands and requirements.

Check out our LEANTECHNIK SYSTEMS projects and find further information in our full catalogue.

Our sales team will be happy to advise you!

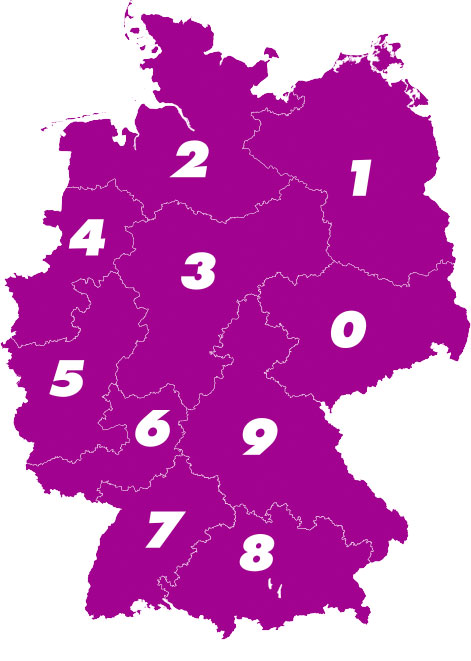

Our sales staff are at your disposal at any time for a non-binding consultation at your premises. To get in touch with your contact person, take a look at who is responsible in your postcode area.

While our product development and design takes place in Oberhausen, our sales staff is at your disposal throughout Germany.

Excellent customer care is part of our understanding of service.

You can find your suitable contact person here:

Head of Sales

Field Service

Sales Manager (international)

ANDREAS SPRENGER

E-Mail: sprenger@leantechnik.com

Phone: +49 208 495 25 65

Mobile: +49 151 57 123 640

MORITZ KNUPLESCH

E-Mail: knuplesch@leantechnik.com

Phone: +49 208 495 25 60

Mobile: +49 151 160 425 84

Key Account Management

Global Key Account Manager

JULIAN BAUKNECHT

E-Mail: bauknecht@leantechnik.com

Telefon: +49 151 527 819 26

Global Key Account Manager

FRIEDRICH KLAEGER

E-Mail: klaeger@leantechnik.com

Telefon: +49 151 647 528 89

Inside Sales

ZIP-Area 0 | 1 | 4 | 5

AMNON SCHÜßLER

E-Mail: schuessler@leantechnik.com

Phone: +49 (0)208 495 25 99

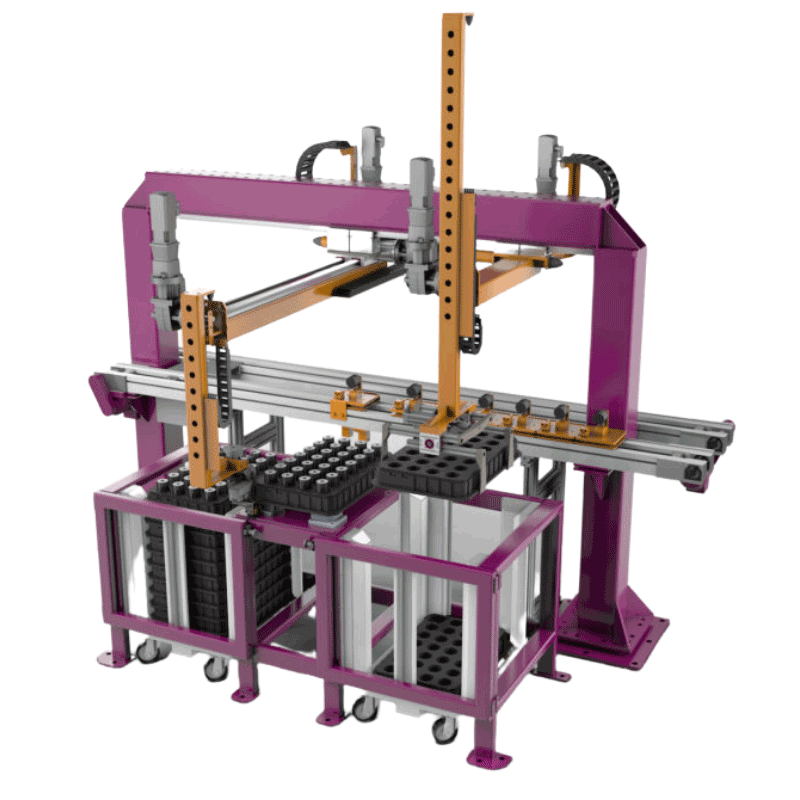

LEANTECHNIK SYSTEMS - Automation with a SYSTEM

The LEANTECHNIK SYSTEMS product division refers to the development and design of partially and functionally ready plants & systems based on our lifgo® and lean SL® gearbox series.

Our motivation:

You provide the ideas – we provide the implementation!

At LEANTECHNIK SYSTEMS, we provide you with the complete know-how and implementation power of our design engineers. We accompany your project from the initial enquiry, through the complete design and planning of your system (incl. service life calculation), right up to implementation on your premises.

Discover:

Lifting Tables Lifting Columns Flexible Positioning Systems Pick & Place & more possibilities

adapted to your needs!

Benefit from the many years of experience of our team of engineers, who are on hand to advise you in the areas of development and design. LEANTECHNIK SYSTEMS stands for customised solutions that are designed especially for you, so that they are precisely tailored to your needs.