LEANTECHNIK P&P

pICK-AND-PLACE

You have the requirements – we have the solutions!

Our division for PICK-AND-PLACE -SYSTEMS:

Our pick-and-place systems have weight. They move even extremely high loads quickly, with high precision and reliably, over many years of operation.

In the following illustrations, the parameters are freely selectable:

Lengths

Spacing

Lifting speed

Loading capacity

Pick-and-Place Systems

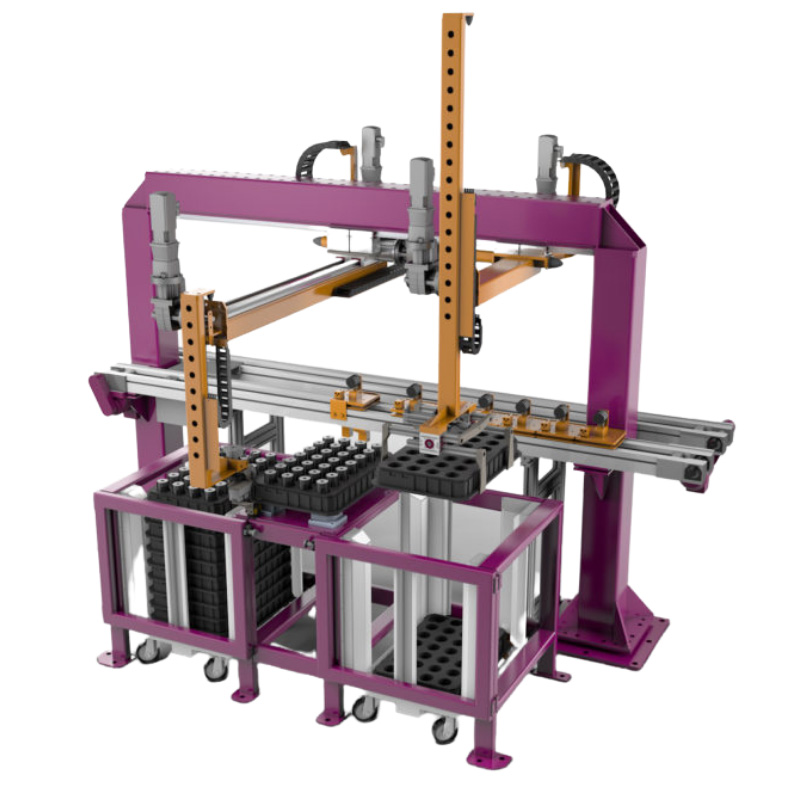

2-axis gantry, variable

2-axis transfer with lifgo® linear for each axis. Grippers, clamps, vacuum devices or other additional devices can be attached to the ends of the rack.

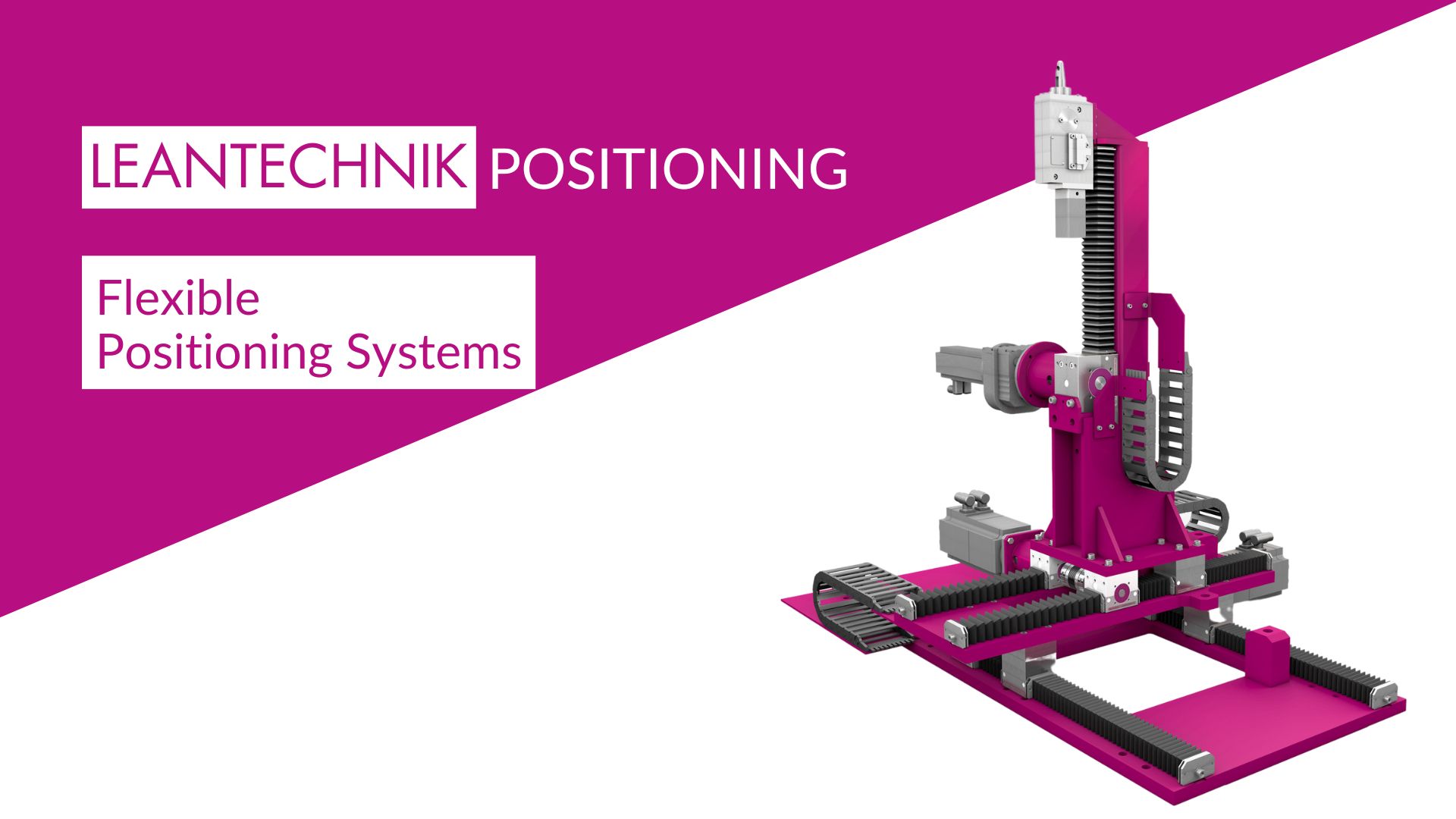

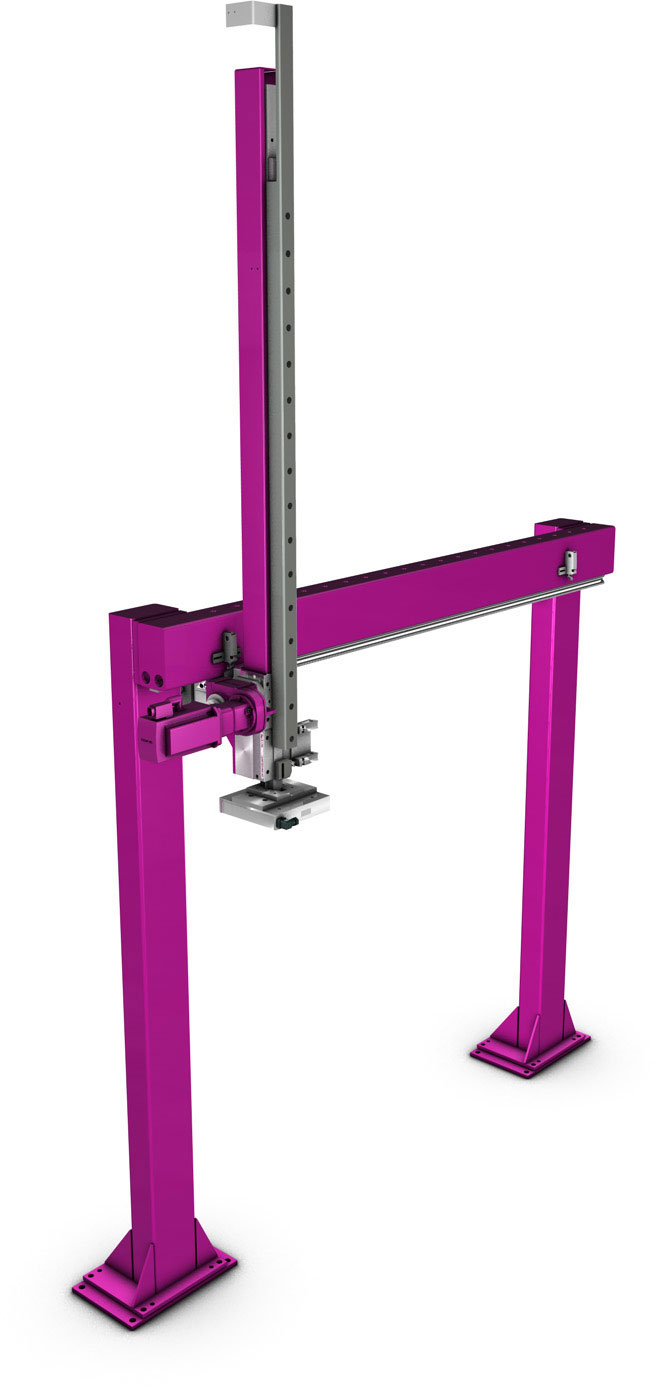

Portal for one-sided access

Compact 3-axis handling system with extendable support arm. Ideal for single-sided access. Compact, fast, precise and low-vibration due to linear guide reinforcement.

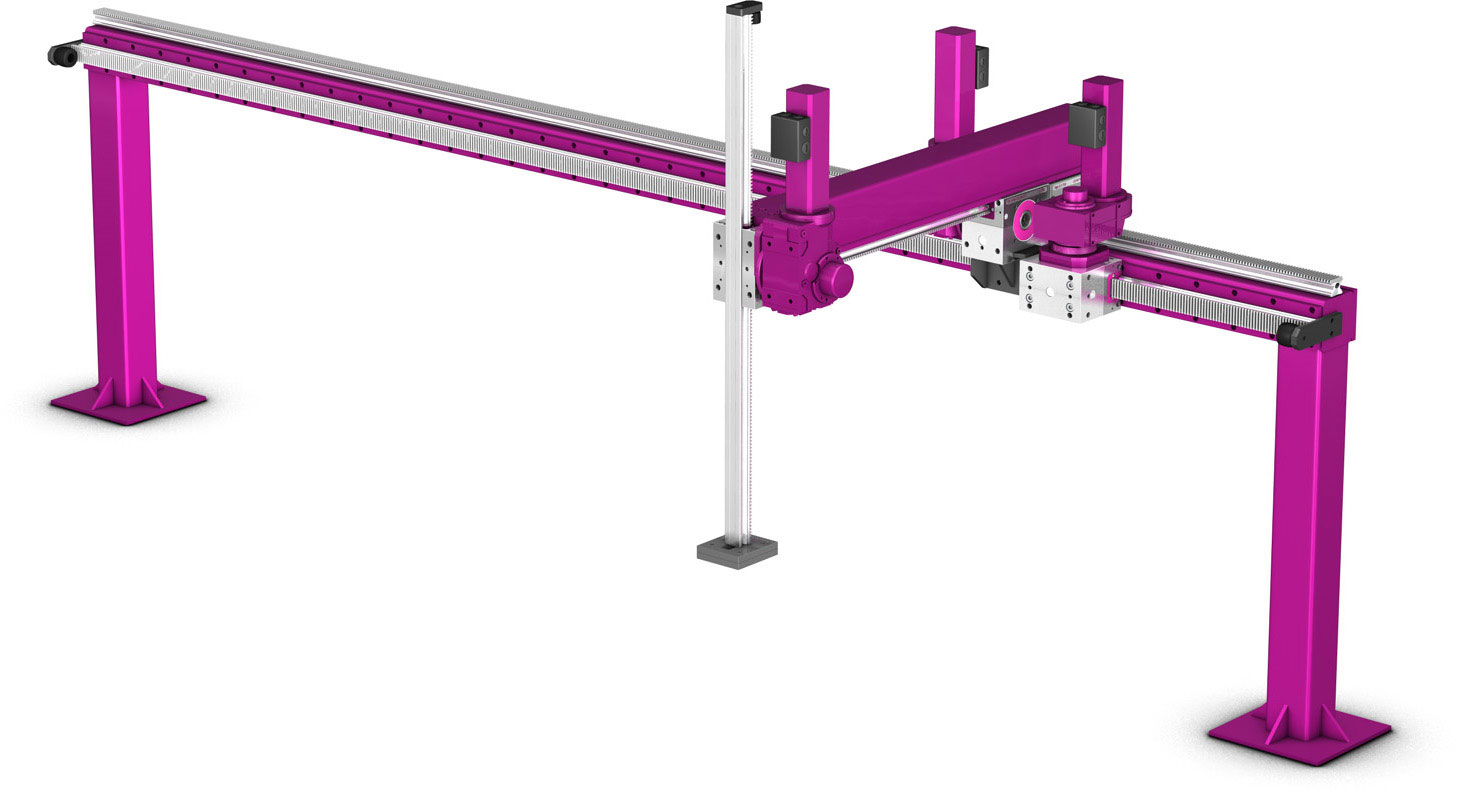

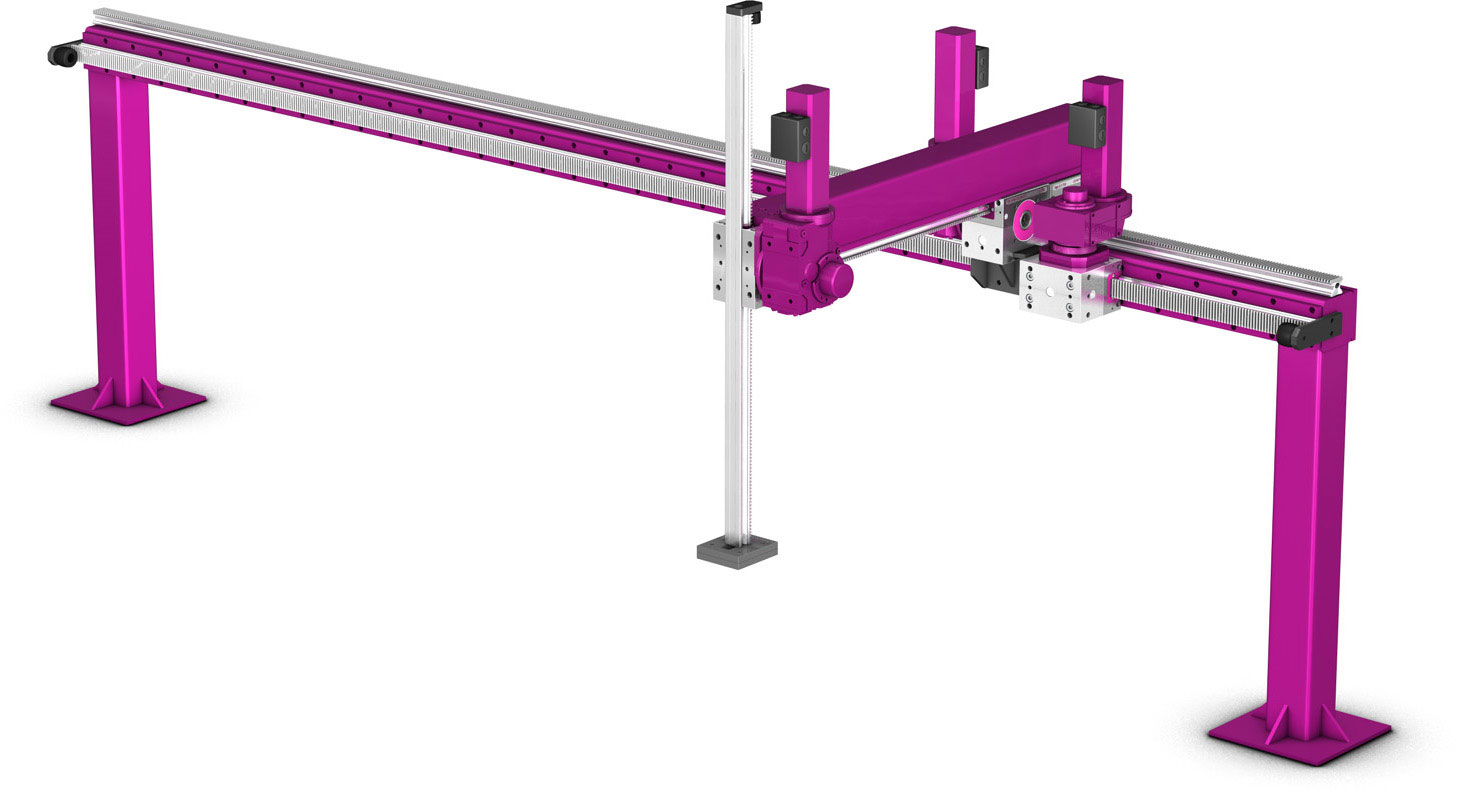

2-axis gantry, variable

2-axis transfer with lifgo® linear for each axis. Grippers, clamps, vacuum devices or other additional devices can be attached to the ends of the rack.

Portal for one-sided access

Compact 3-axis handling system with extendable support arm. Ideal for single-sided access. Compact, fast, precise and low-vibration due to linear guide reinforcement.

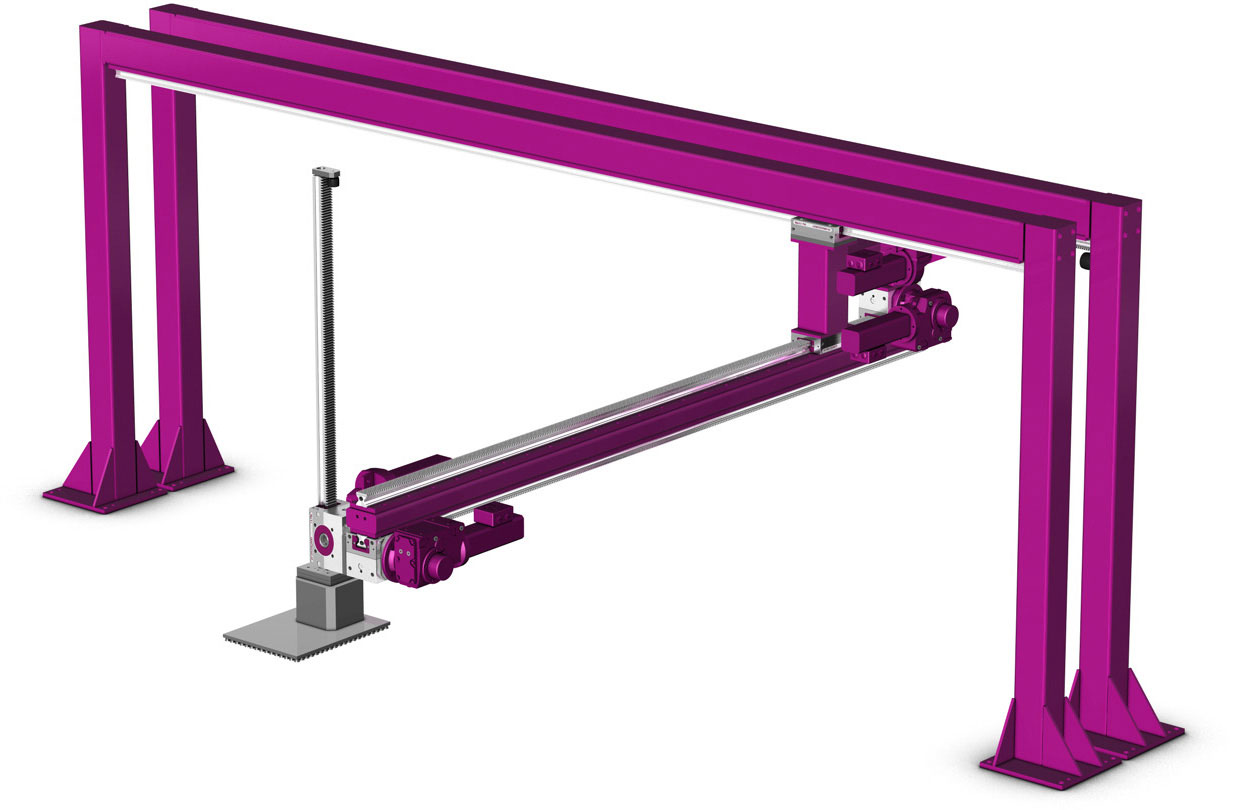

2-axis gantry with 2 vertical axes

Portal with two lifgo® linear and an additional lifgo® guide. Two lifgo® for the Z-axis are mounted on top of this. Additional devices are attached to the rack ends.

4-axis system with rotary head and suction cup

4-axis "Pick&Place" system with linear movement. The fifth axis is used as a decentralised rotary axis with suction cup or magnet. This application is used to pick up surface-optimised cut parts (sheets, etc.) and to stack the parts congruently on opposite pallets.

2-axis gantry with 2 vertical axes

Portal with two lifgo® linear and an additional lifgo® guide. Two lifgo® for the Z-axis are mounted on top of this. Additional devices are attached to the rack ends.

4-axis system with rotary head and suction cup

4-axis "Pick&Place" system with linear movement. The fifth axis is used as a decentralised rotary axis with suction cup or magnet. This application is used to pick up surface-optimised cut parts (sheets, etc.) and to stack the parts congruently on opposite pallets.

Pick-and-Place Systems – in action!

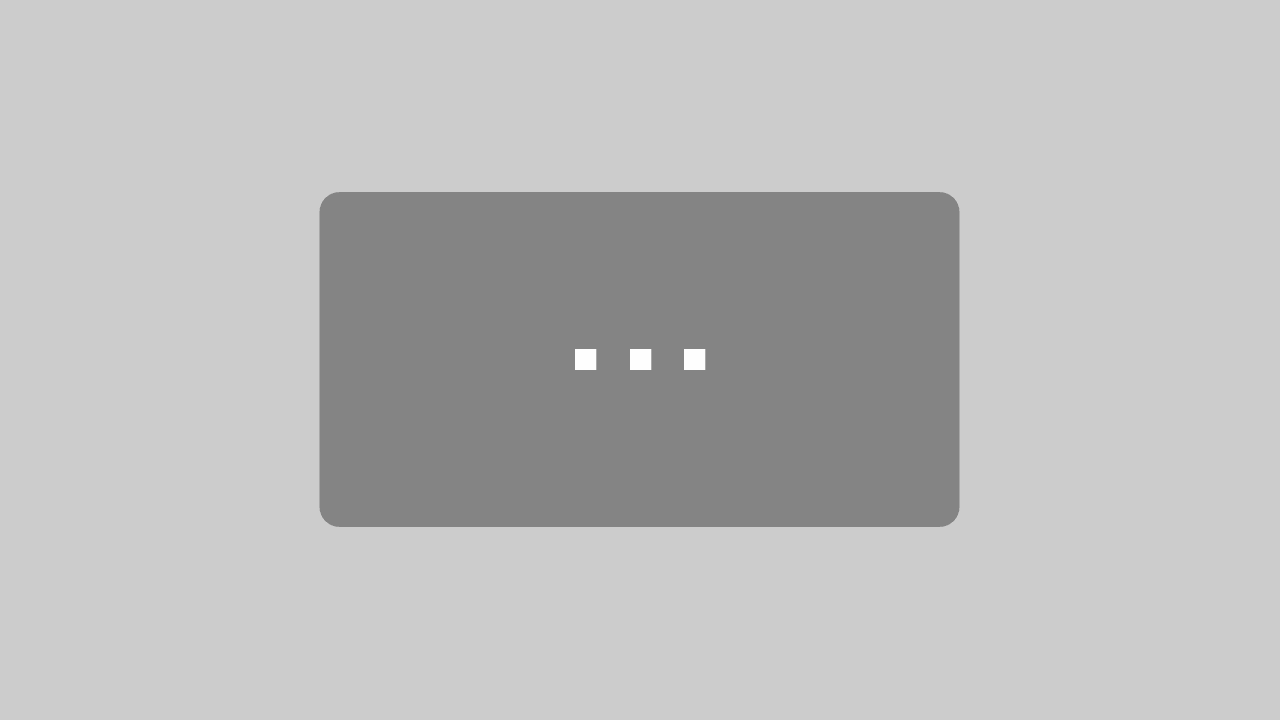

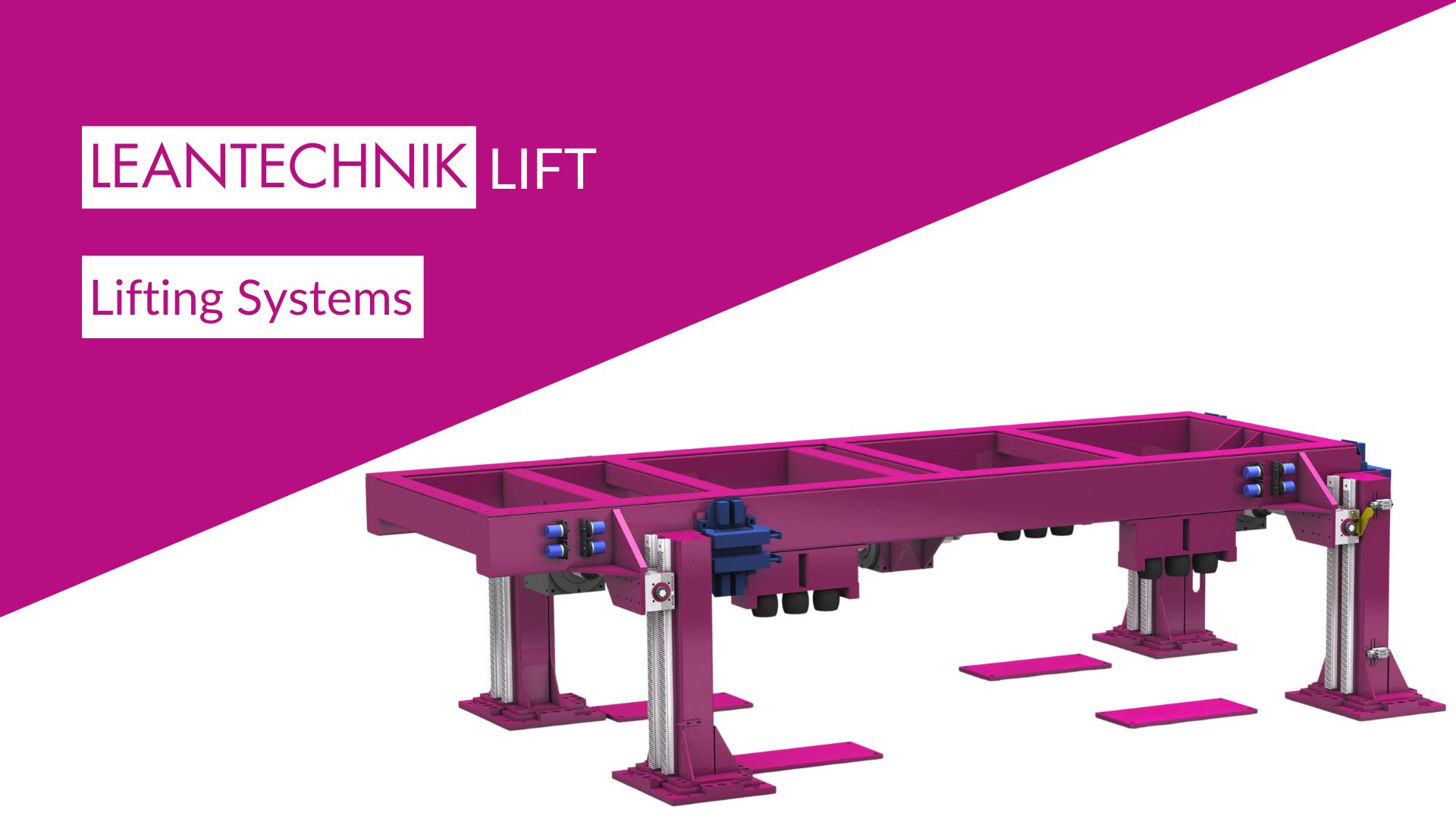

LEANTECHNIK SYSTEMS – Automation with SYSTEM

The LEANTECHNIK SYSTEMS product division refers to the development and design of partially and functionally ready plants & systems based on our lifgo® and lean SL® gearbox series.

Our motivation:

You provide the ideas – we provide the implementation!

At LEANTECHNIK SYSTEMS, we provide you with the complete know-how and implementation power of our design engineers. We accompany your project from the initial enquiry, through the complete design and planning of your system (incl. service life calculation), right up to implementation on your premises.

Discover:

Lifting Tables Lifting Columns Flexible Positioning Systems Pick & Place & & more possibilities

adapted to your needs!

Benefit from the many years of experience of our team of engineers, who are on hand to advise you in the areas of development and design. LEANTECHNIK SYSTEMS stands for customised solutions that are designed especially for you, so that they are precisely tailored to your needs.

LEANTECHNIK SYSTEMS - Discover the LEANTECHNIK system solutions & complete systems

With lifgo® and lean SL® we will find the perfect solution for your

the perfect solution for your specific case.

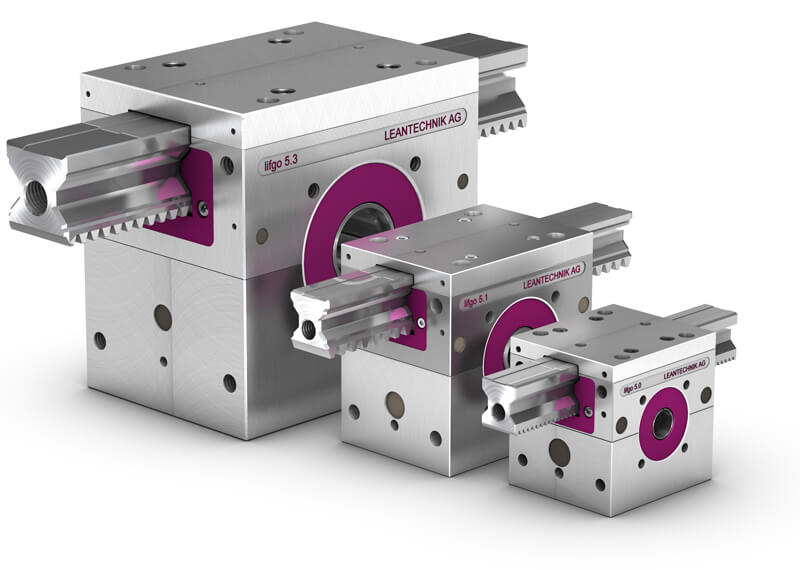

lifgo®

This linear-guided rack and pinion screw jack is suitable for fast, precise and synchronous installations. For applications requiring high lateral force absorption, our resilient and durable lifgo® series is the first choice.

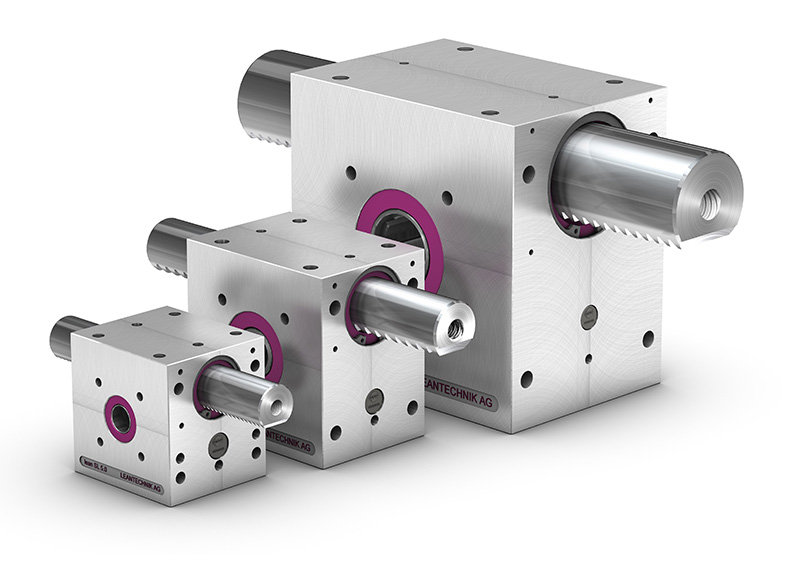

lean SL®

The robust and inexpensive alternative to the lifgo®. The gear unit is suitable for simple synchronous lifting tasks where an exact guide is already available and a transverse force absorption is not required.