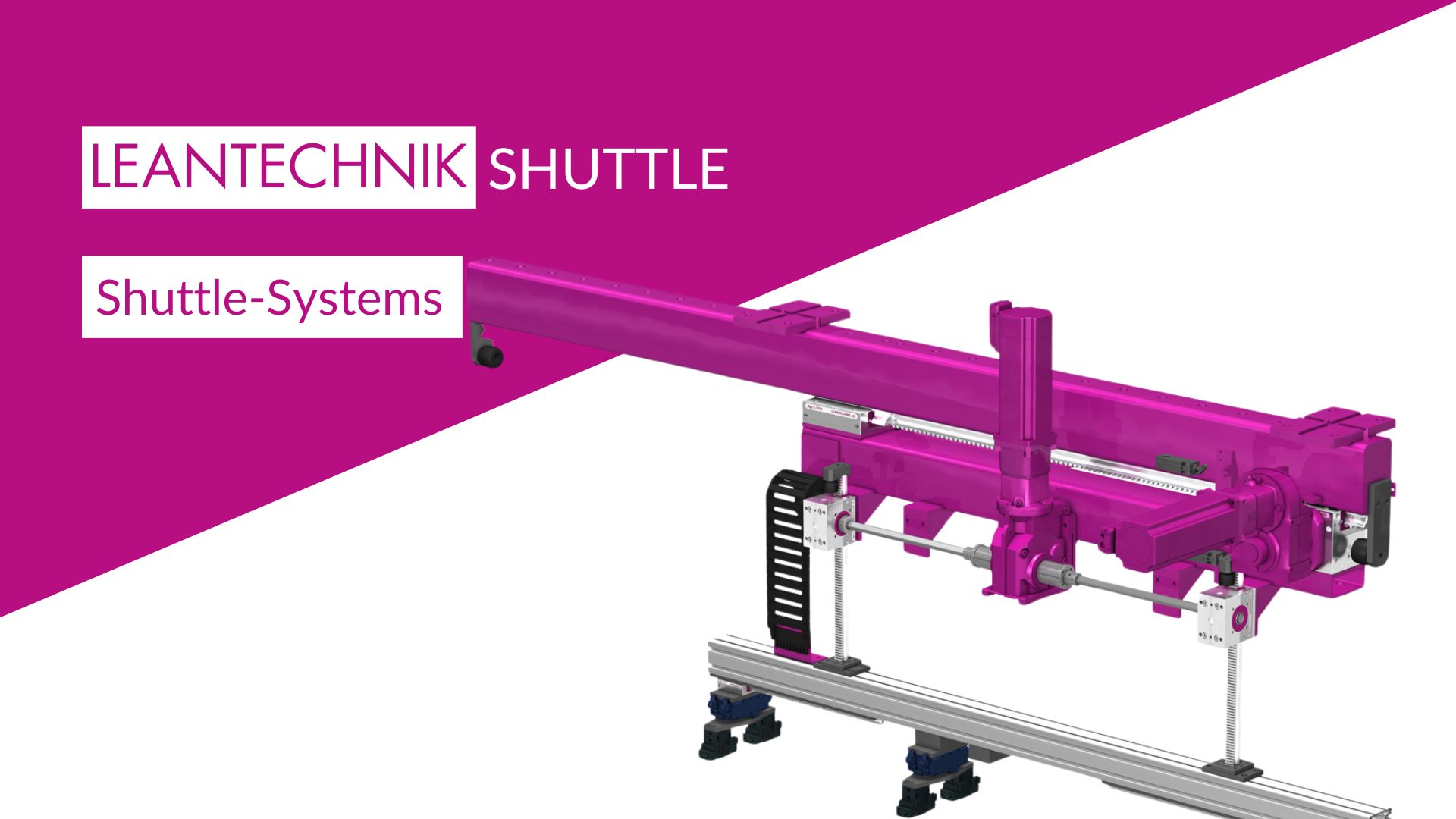

LEANTECHNIK SHUTTLE

sHUTTLE-sYSTEMs

You have the requirements – we have the solutions!

Our division for SHUTTLE SYSTEMS:

In many factories, materials or components have to be transported from one processing station to the next in a short time. This is only possible with transfer and shuttle systems that are precisely adapted to their task. These systems should be resilient, compact and above all fast.

In the following illustrations, the parameters are freely selectable:

Lengths

Spacing

Lifting speed

Loading capacity

Shuttle - Systems

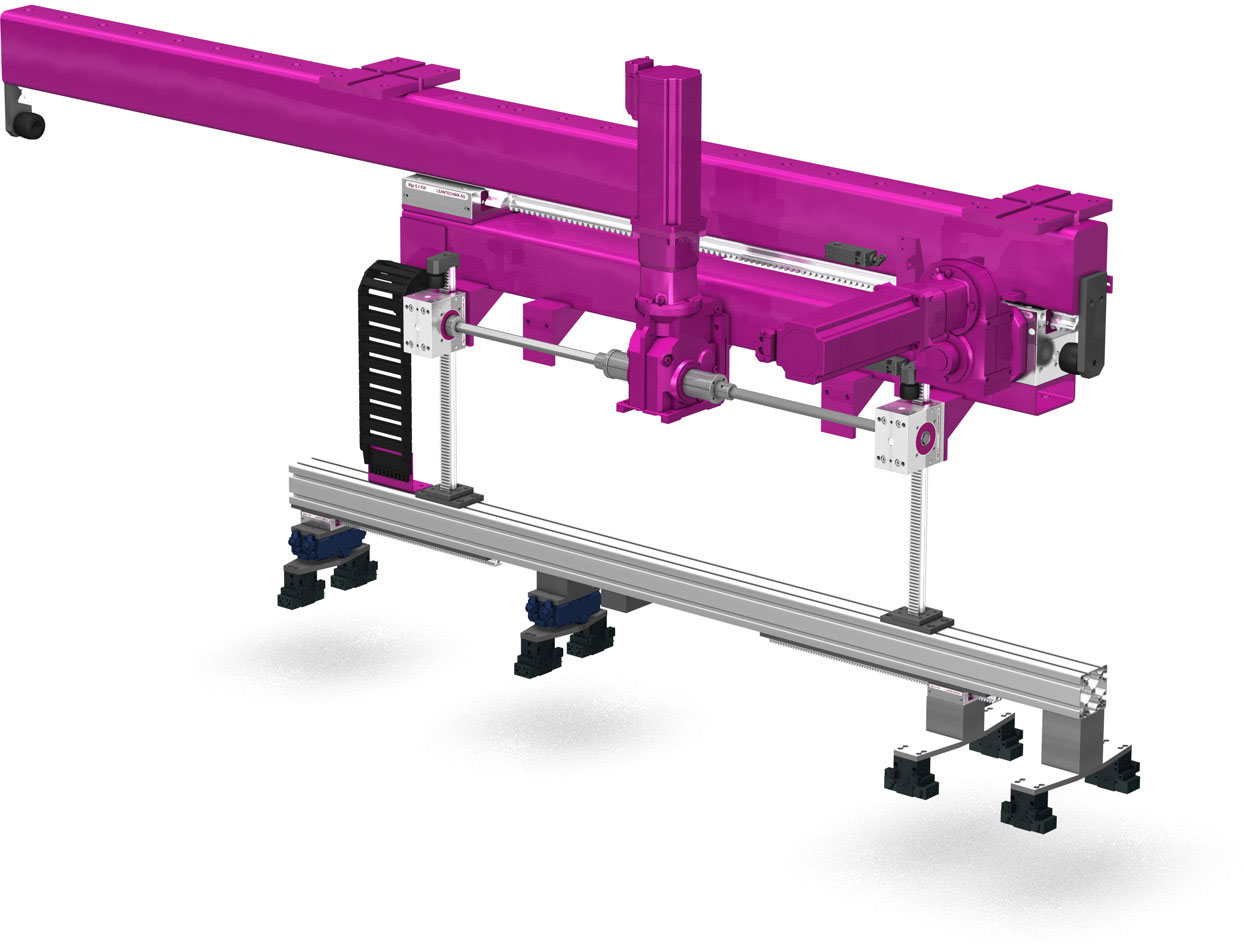

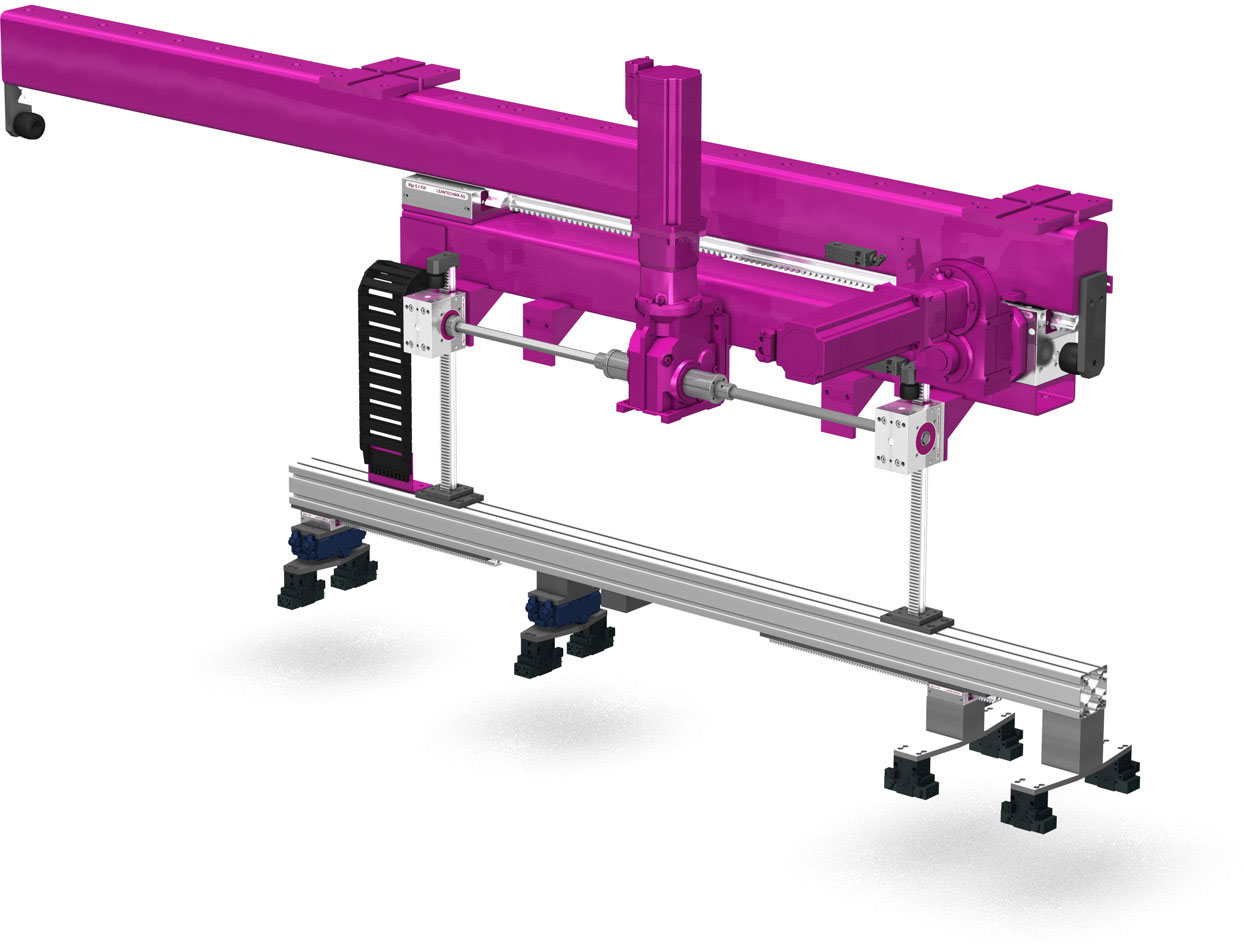

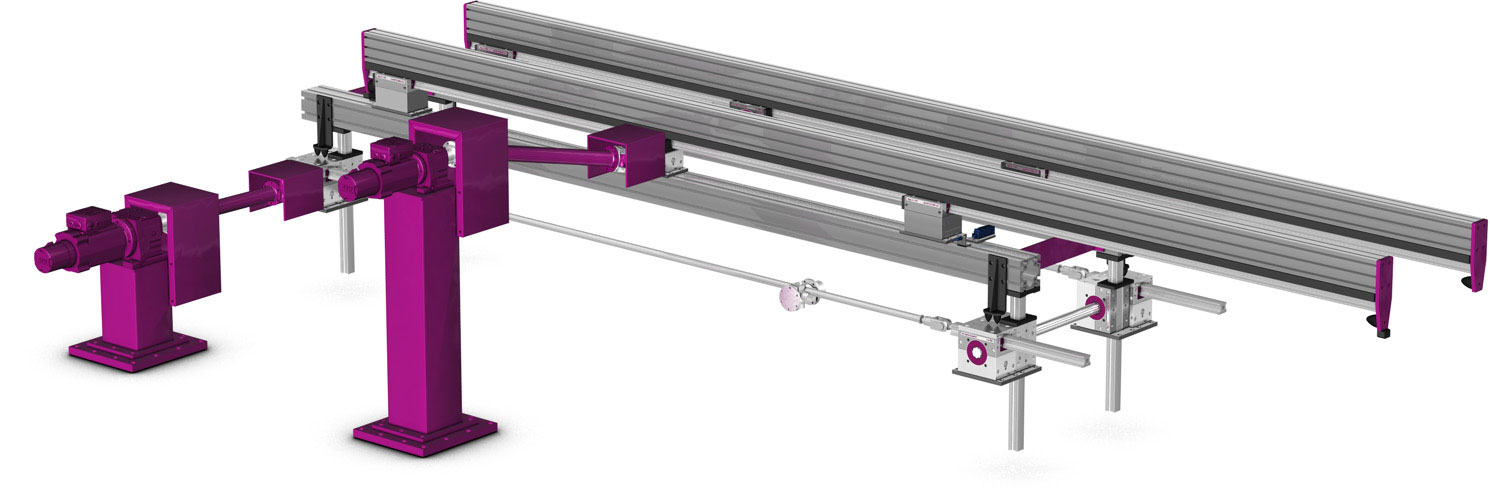

1-arm shuttle, suspended, 2-axle drive

Suspended 1-beam shuttle. The rack and lifgo® linear are suspended under the beam for the horizontal drive. The superstructure and two lifgo® for the Z-stroke are attached to this. Grippers, suction cups or other devices can now be mounted on the suspended standard aluminium profile.

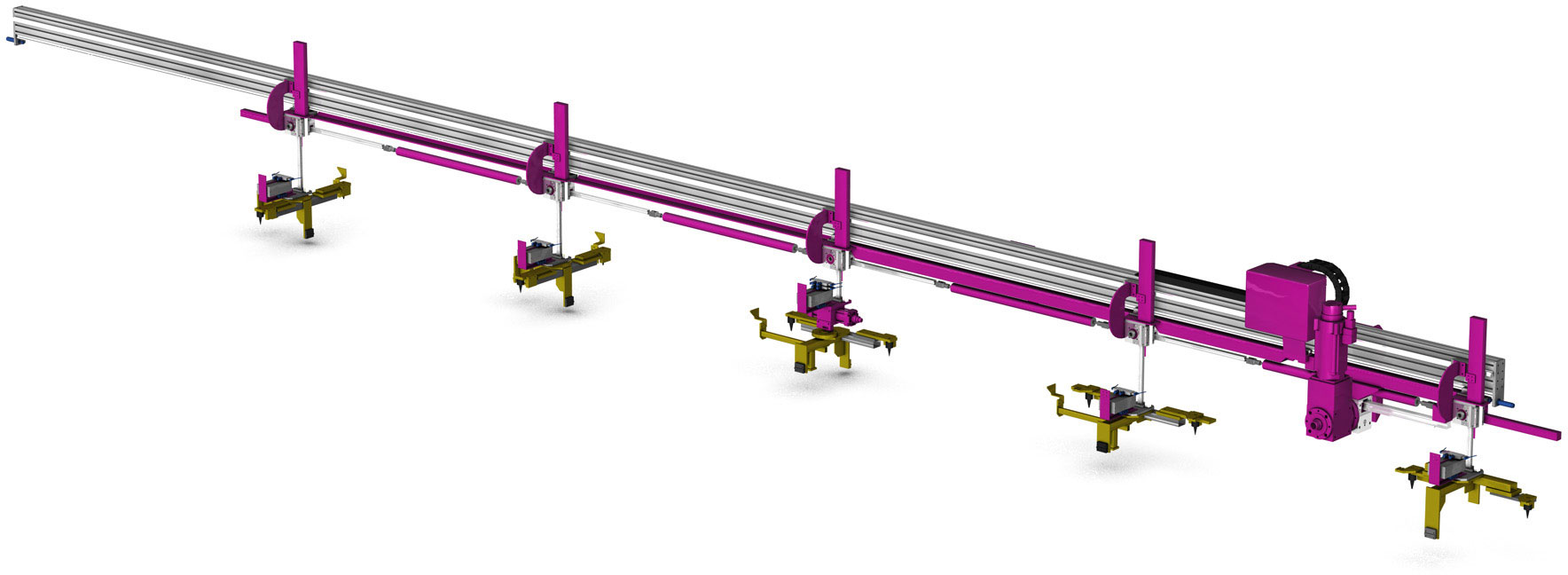

1-arm shuttle, suspended, 2-axis drive with 5 gripper stations

The horizontal lift is mounted in a suspended position. In contrast to the previous example, the vertical lift has been designed so that a second lifgo® gearbox is mounted in the horizontal direction next to each vertically aligned one. The gearboxes are each connected and synchronised via a profile shaft. In the horizontal direction, a tensile force is exerted on the racks, which causes the pinions to rotate. This force is transferred to the vertical lifgo® , and the rotation is redirected back into a linear movement (vertical in this case).

1-arm shuttle, suspended, 2-axle drive

Suspended 1-beam shuttle. The rack and lifgo® linear are suspended under the beam for the horizontal drive. The superstructure and two lifgo® for the Z-stroke are attached to this. Grippers, suction cups or other devices can now be mounted on the suspended standard aluminium profile.

1-arm shuttle, suspended, 2-axis drive with 5 gripper stations

The horizontal lift is mounted in a suspended position. In contrast to the previous example, the vertical lift has been designed so that a second lifgo® gearbox is mounted in the horizontal direction next to each vertically aligned one. The gearboxes are each connected and synchronised via a profile shaft. In the horizontal direction, a tensile force is exerted on the racks, which causes the pinions to rotate. This force is transferred to the vertical lifgo® , and the rotation is redirected back into a linear movement (vertical in this case).

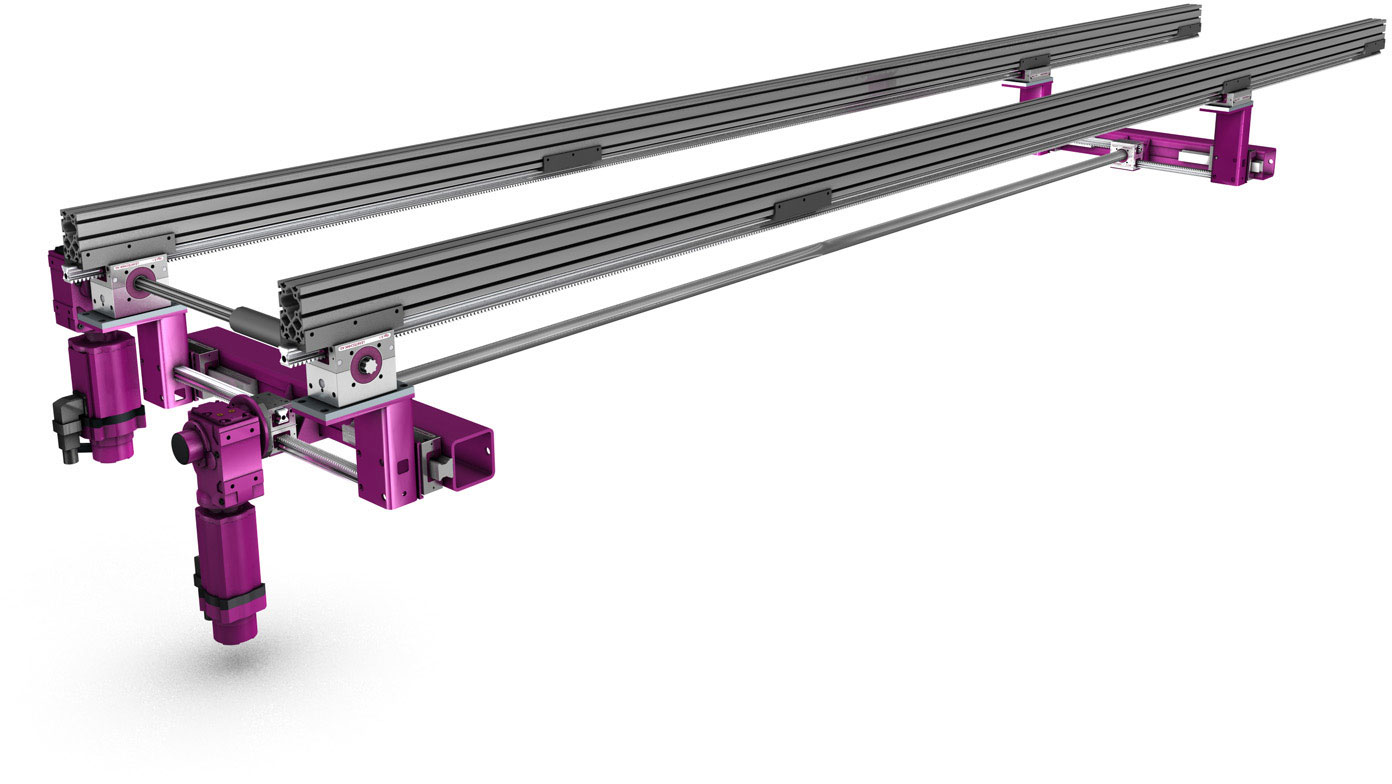

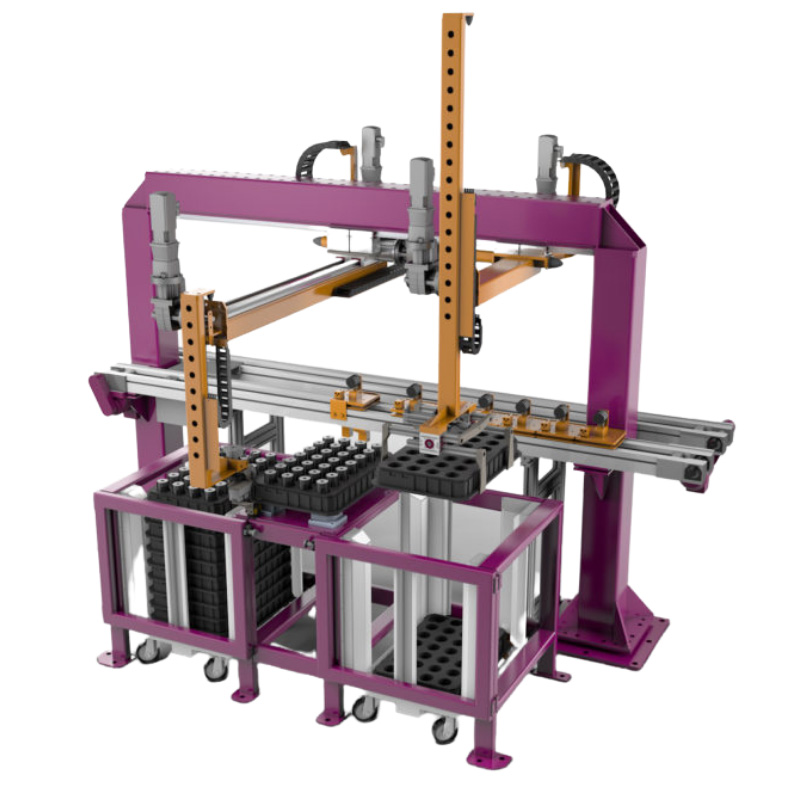

2-axis transfer with gripper function

Standing 2-axis transfer parts conveyor. One lifting axis horizontal, one gripper or closing axis, synchronous from both sides to the centre. Can be used as a step conveyor. Also available as 3-axis transfer with horizontal and vertical stroke and synchronous closing axis.

2-arm shuttle, standing, 2-axle drive from outside

Designed as a 2-axis transfer shuttle with externally mounted drives. The system can also be designed as a 3-axis transfer gripper shuttle.

2-axis transfer with gripper function

Standing 2-axis transfer parts conveyor. One lifting axis horizontal, one gripper or closing axis, synchronous from both sides to the centre. Can be used as a step conveyor. Also available as 3-axis transfer with horizontal and vertical stroke and synchronous closing axis.

2-arm shuttle, standing, 2-axle drive from outside

Designed as a 2-axis transfer shuttle with externally mounted drives. The system can also be designed as a 3-axis transfer gripper shuttle.

Shuttle – Systems – in action!

LEANTECHNIK SYSTEMS – Automation with SYSTEM

The LEANTECHNIK SYSTEMS product division refers to the development and design of partially and functionally ready plants & systems based on our lifgo® and lean SL® gearbox series.

Our motivation:

You provide the ideas – we provide the implementation!

At LEANTECHNIK SYSTEMS, we provide you with the complete know-how and implementation power of our design engineers. We accompany your project from the initial enquiry, through the complete design and planning of your system (incl. service life calculation), right up to implementation on your premises.

Discover:

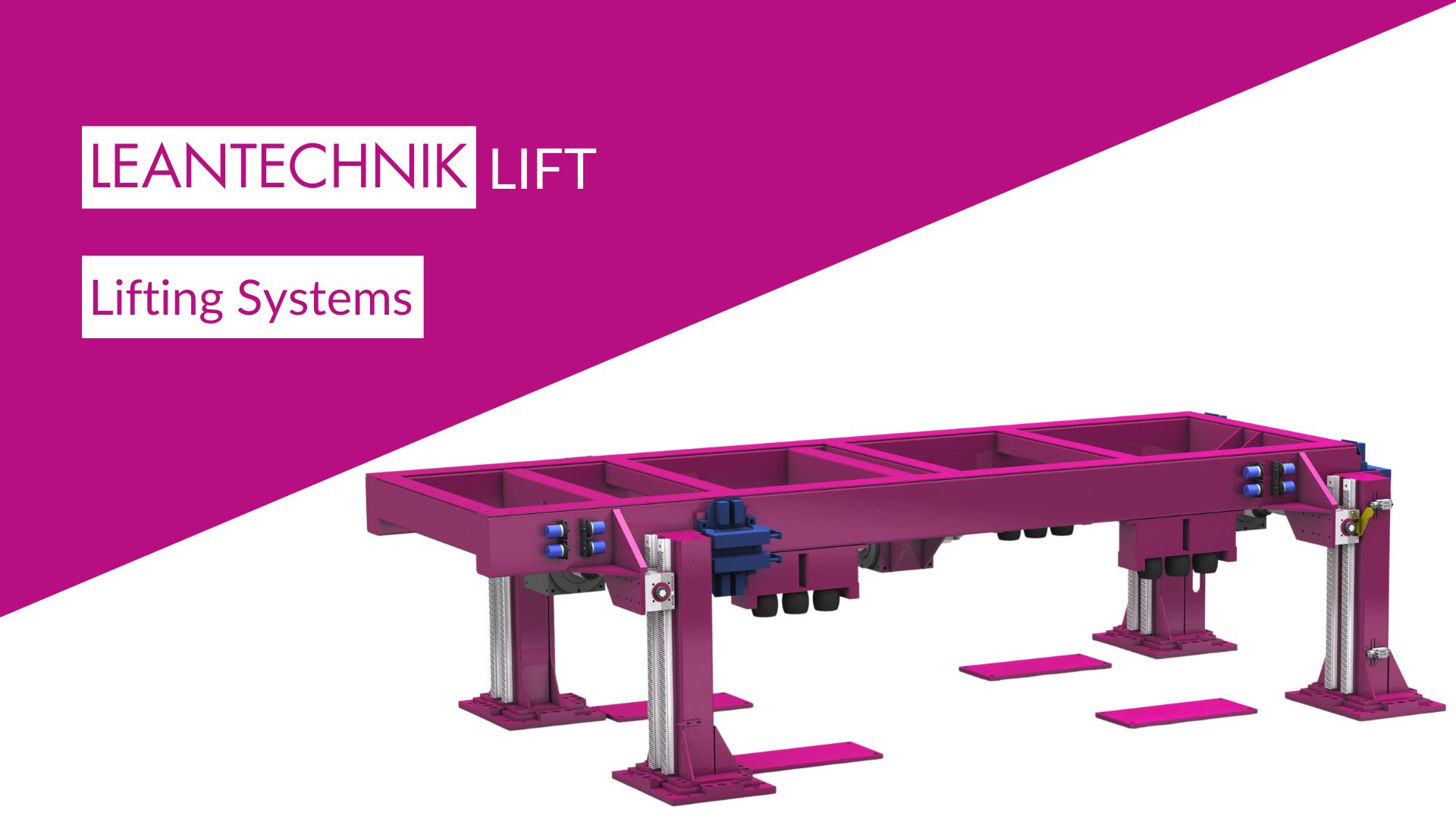

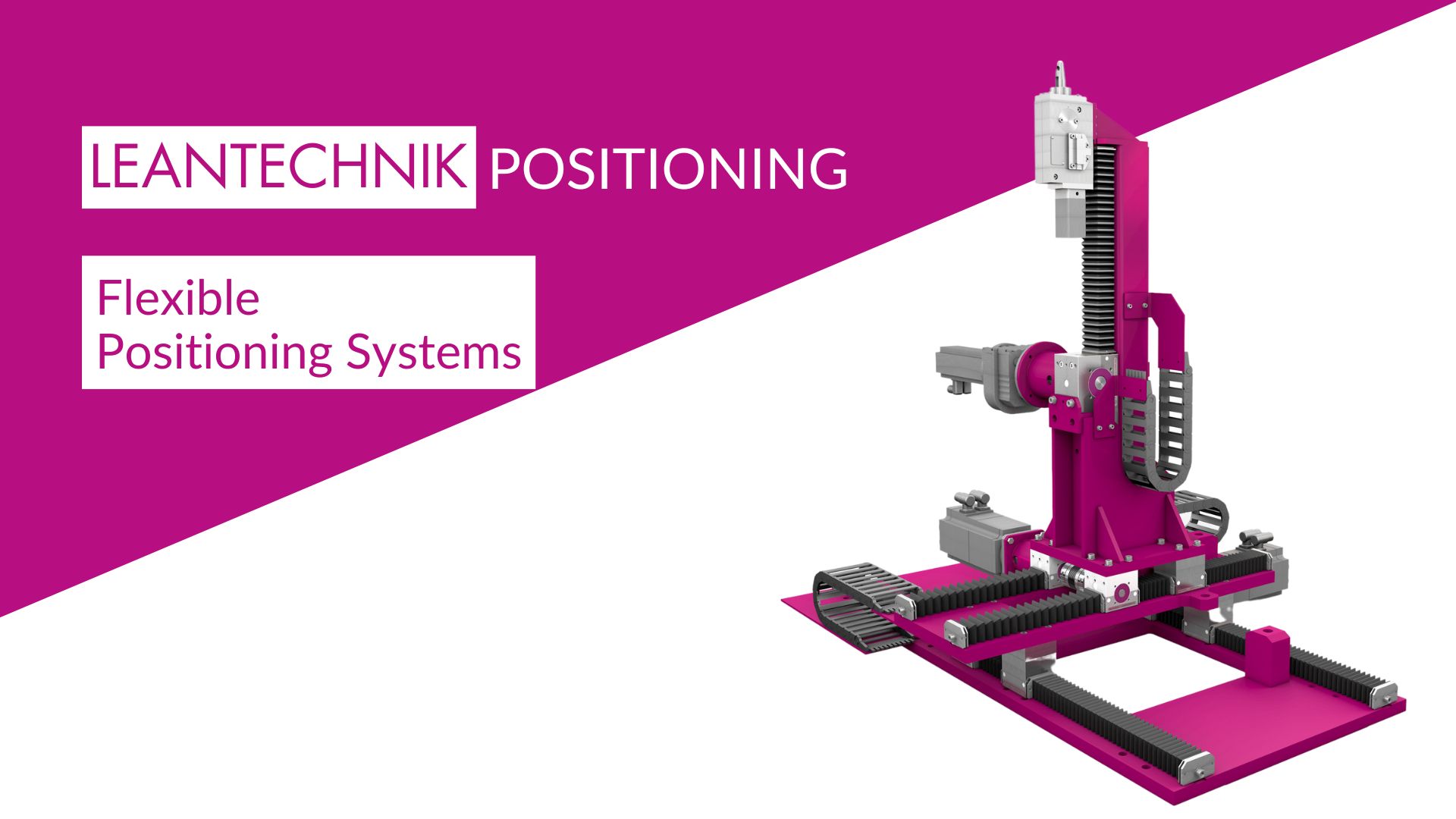

Lifting Tables Lifting Columns Flexible Positioning Systems Pick & Place & & more possibilities

adapted to your needs!

Benefit from the many years of experience of our team of engineers, who are on hand to advise you in the areas of development and design. LEANTECHNIK SYSTEMS stands for customised solutions that are designed especially for you, so that they are precisely tailored to your needs.

LEANTECHNIK SYSTEMS - Discover the LEANTECHNIK system solutions & complete systems

With lifgo® and lean SL® we will find the perfect solution for your

the perfect solution for your specific case.

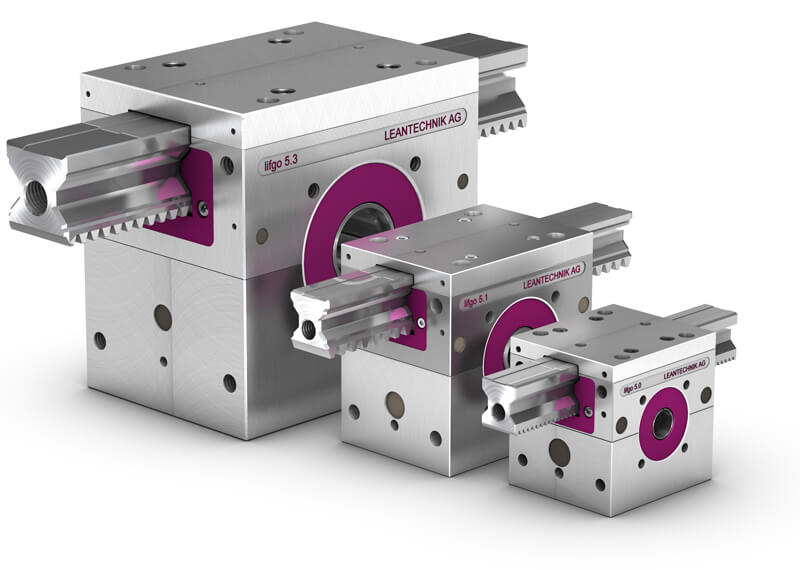

lifgo®

This linear-guided rack and pinion screw jack is suitable for fast, precise and synchronous installations. For applications requiring high lateral force absorption, our resilient and durable lifgo® series is the first choice.

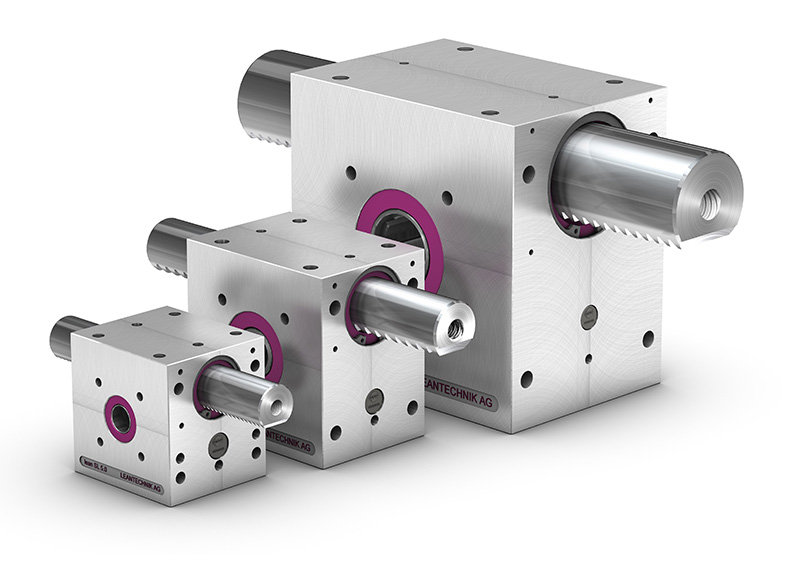

lean SL®

The robust and inexpensive alternative to the lifgo®. The gear unit is suitable for simple synchronous lifting tasks where an exact guide is already available and a transverse force absorption is not required.