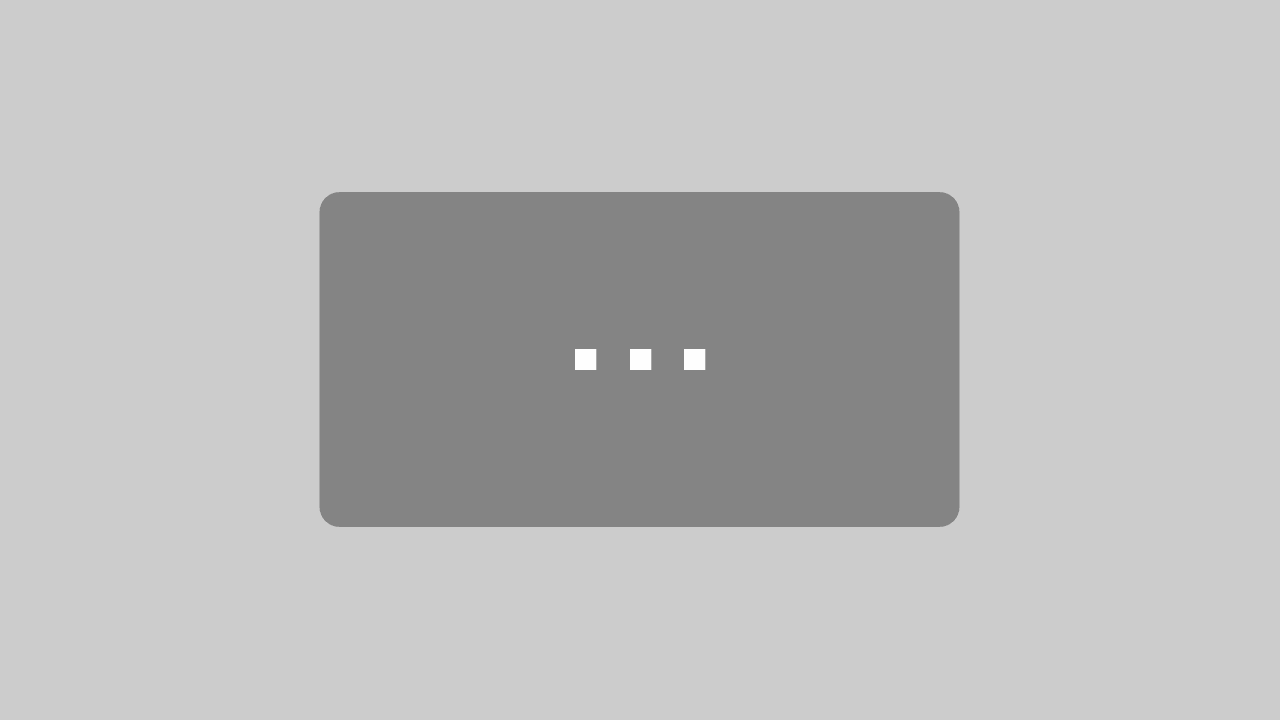

Do you want to GO HIGHER?!

With Lifting Columns of LEANTECHNIK – No Problem!

High Speed

Tight Operating Parameters

Low Maintenance

Highest Precision

Simple Installation

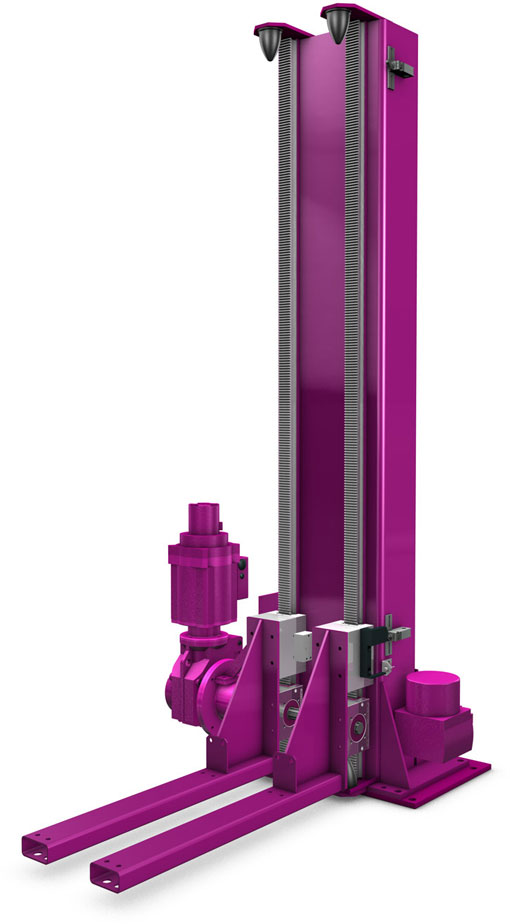

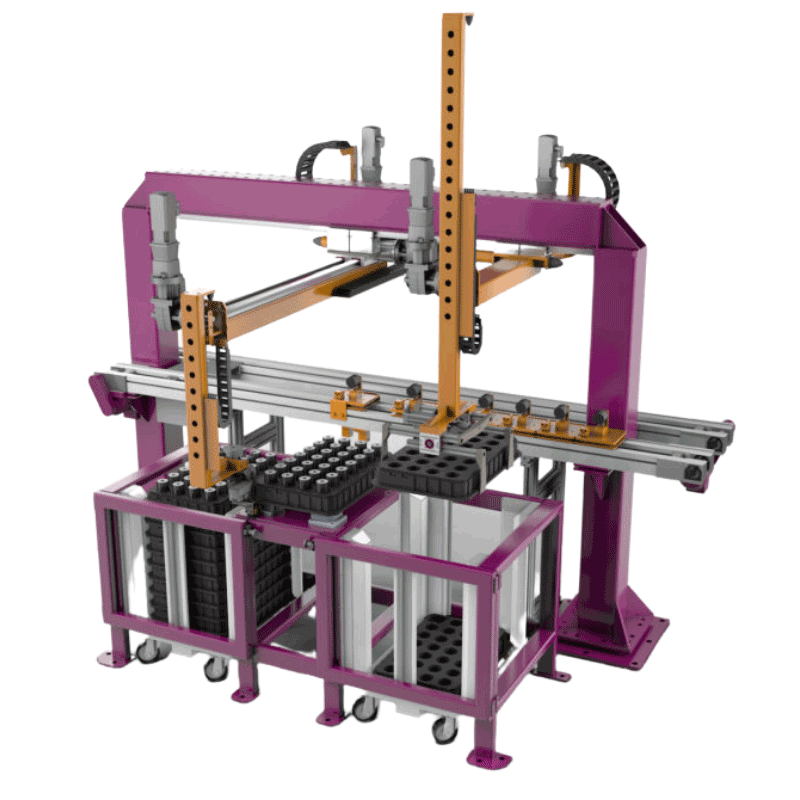

In the assembly of a Lifting system, we encountered the challenges of an assembly space that had a ceiling height of only 3.2 meters (10.5 feet). Despite the limitations of the production area, our engineers were able to install the Lifting Column successfully. In 3 seconds, the Lifting System can travel up to 1800 mm (70 inches) and handle a capacity up to 850 kg (1870 lbs ). The Gear Rack Drive, lifgo® linear 5.3 Series, each have a lifting force of 15,000 N and travel on a rack in the operational range of the Lifting Column.

Benefit from our experienced engineering team.

They are prepared to assist with design and development recommendations of cutting-edge solutions that meet your demands and requirements.

Check out our LEANTECHNIK SYSTEMS projects and find further information in our full catalogue.

Our sales team will be happy to advise you!

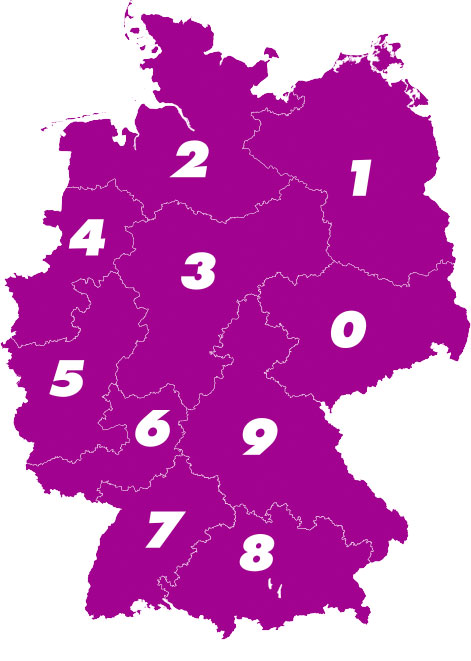

Our sales staff are at your disposal at any time for a non-binding consultation at your premises. To get in touch with your contact person, take a look at who is responsible in your postcode area.

While our product development and design takes place in Oberhausen, our sales staff is at your disposal throughout Germany.

Excellent customer care is part of our understanding of service.

You can find your suitable contact person here:

Head of Sales

Field Service

Sales Manager (international)

ANDREAS SPRENGER

E-Mail: sprenger@leantechnik.com

Phone: +49 208 495 25 65

Mobile: +49 151 57 123 640

MORITZ KNUPLESCH

E-Mail: knuplesch@leantechnik.com

Phone: +49 208 495 25 60

Mobile: +49 151 160 425 84

Key Account Management

Global Key Account Manager

JULIAN BAUKNECHT

E-Mail: bauknecht@leantechnik.com

Telefon: +49 151 527 819 26

Global Key Account Manager

FRIEDRICH KLAEGER

E-Mail: klaeger@leantechnik.com

Telefon: +49 151 647 528 89

Inside Sales

ZIP-Area 0 | 1 | 4 | 5

AMNON SCHÜßLER

E-Mail: schuessler@leantechnik.com

Phone: +49 (0)208 495 25 99

LEANTECHNIK SYSTEMS - Automation with a SYSTEM

The LEANTECHNIK SYSTEMS product division refers to the development and design of partially and functionally ready plants & systems based on our lifgo® and lean SL® gearbox series.

Our motivation:

You provide the ideas – we provide the implementation!

At LEANTECHNIK SYSTEMS, we provide you with the complete know-how and implementation power of our design engineers. We accompany your project from the initial enquiry, through the complete design and planning of your system (incl. service life calculation), right up to implementation on your premises.

Discover:

Lifting Tables Lifting Columns Flexible Positioning Systems Pick & Place & more possibilities

adapted to your needs!

Benefit from the many years of experience of our team of engineers, who are on hand to advise you in the areas of development and design. LEANTECHNIK SYSTEMS stands for customised solutions that are designed especially for you, so that they are precisely tailored to your needs.