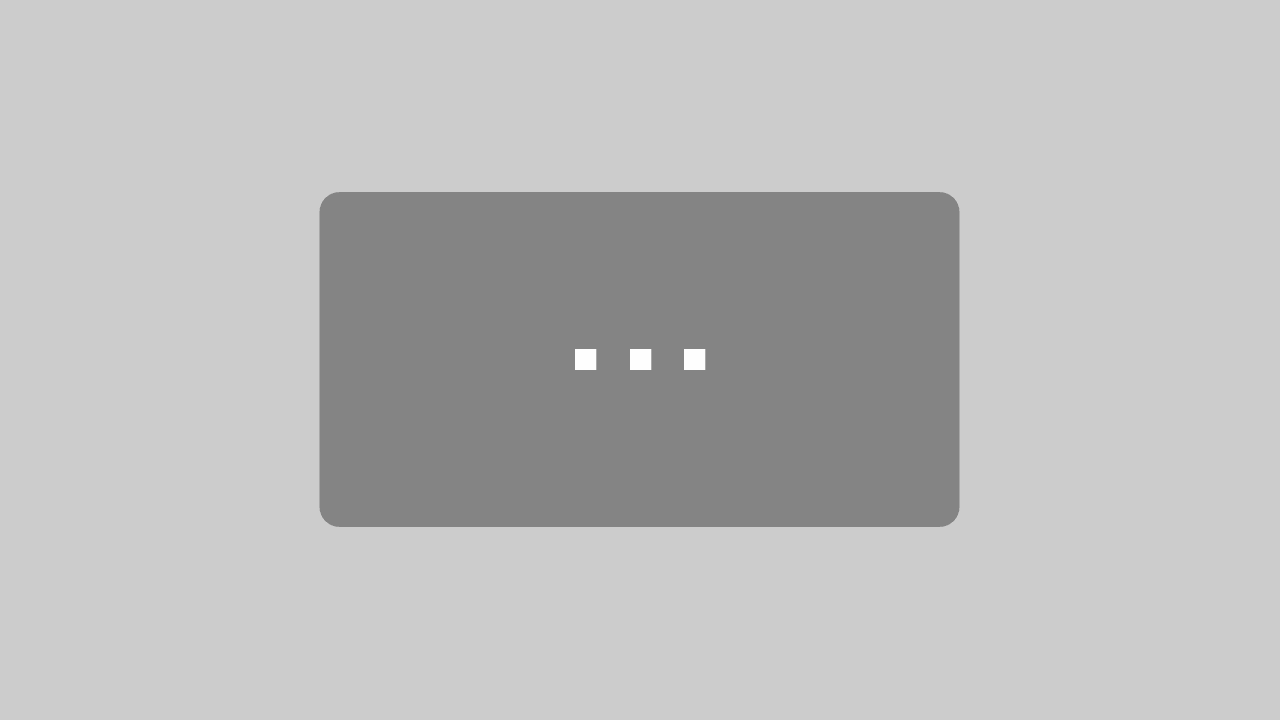

LEANTECHNIK LIFT

Lifting systems

You have the requirement – we have the solution!

Our division for lifting systems:

Whether lifting tables, lifting columns or elevating conveyors, with LEANTECHNIK lifting systems you can raise your production to a new level. High-precision, extremely resilient & tailored to your needs.

In the following illustrations, the parameters are freely selectable:

Lengths

Spacing

Lifting speed

Loading capacity

Synchronous lifting systems

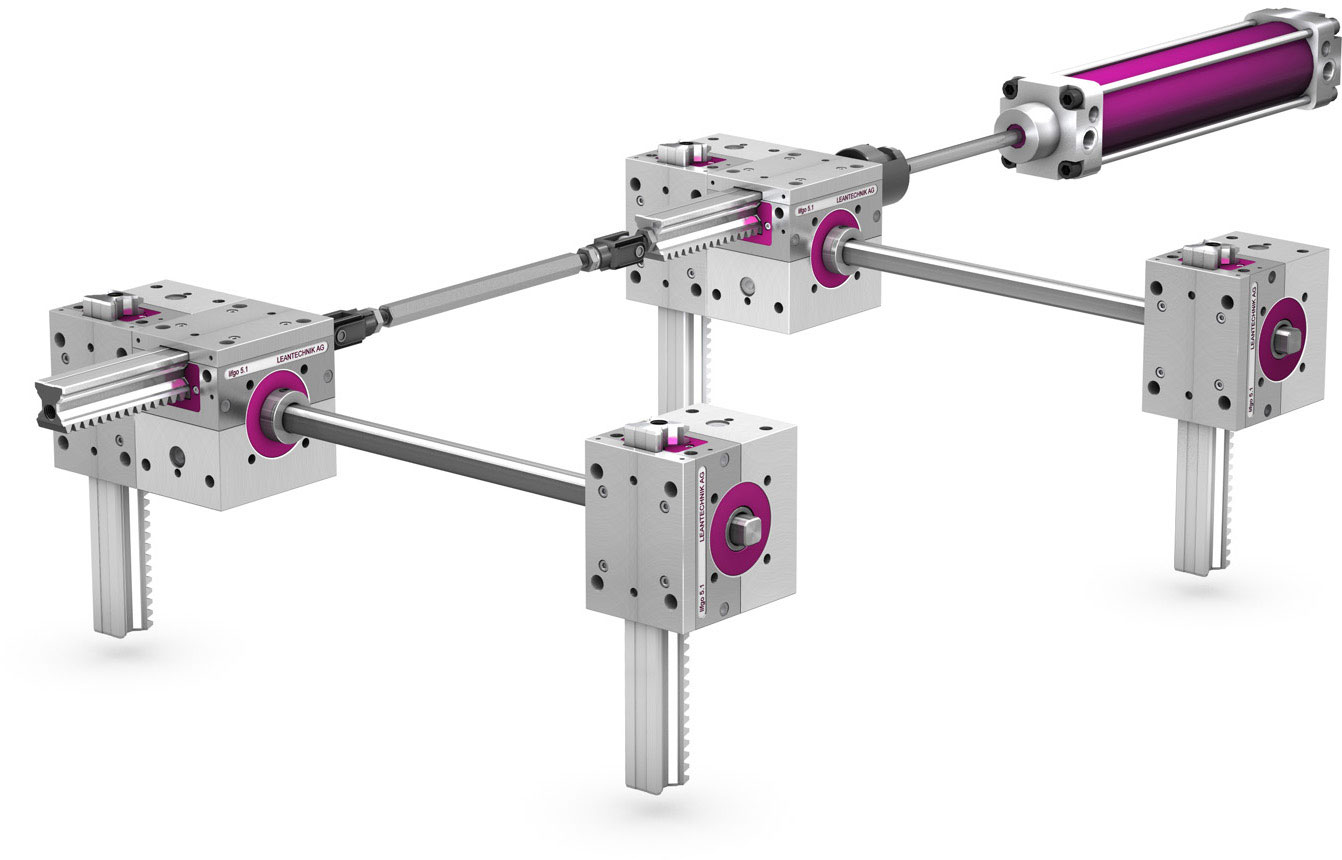

Standard lifting system with lifgo® and air cylinder drive

The two primary gear units of the lifgo® series each distribute half of the maximum possible force to the four gear units with vertical rack. The lifgo® racks guide overhead loads and can absorb lateral forces.

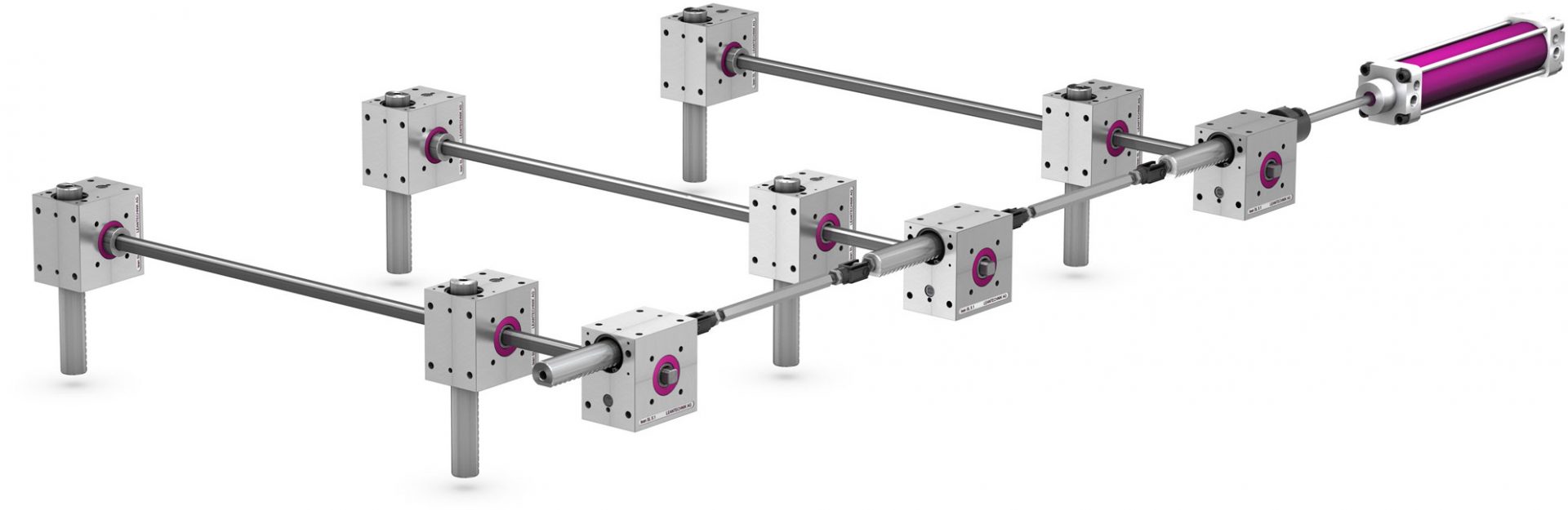

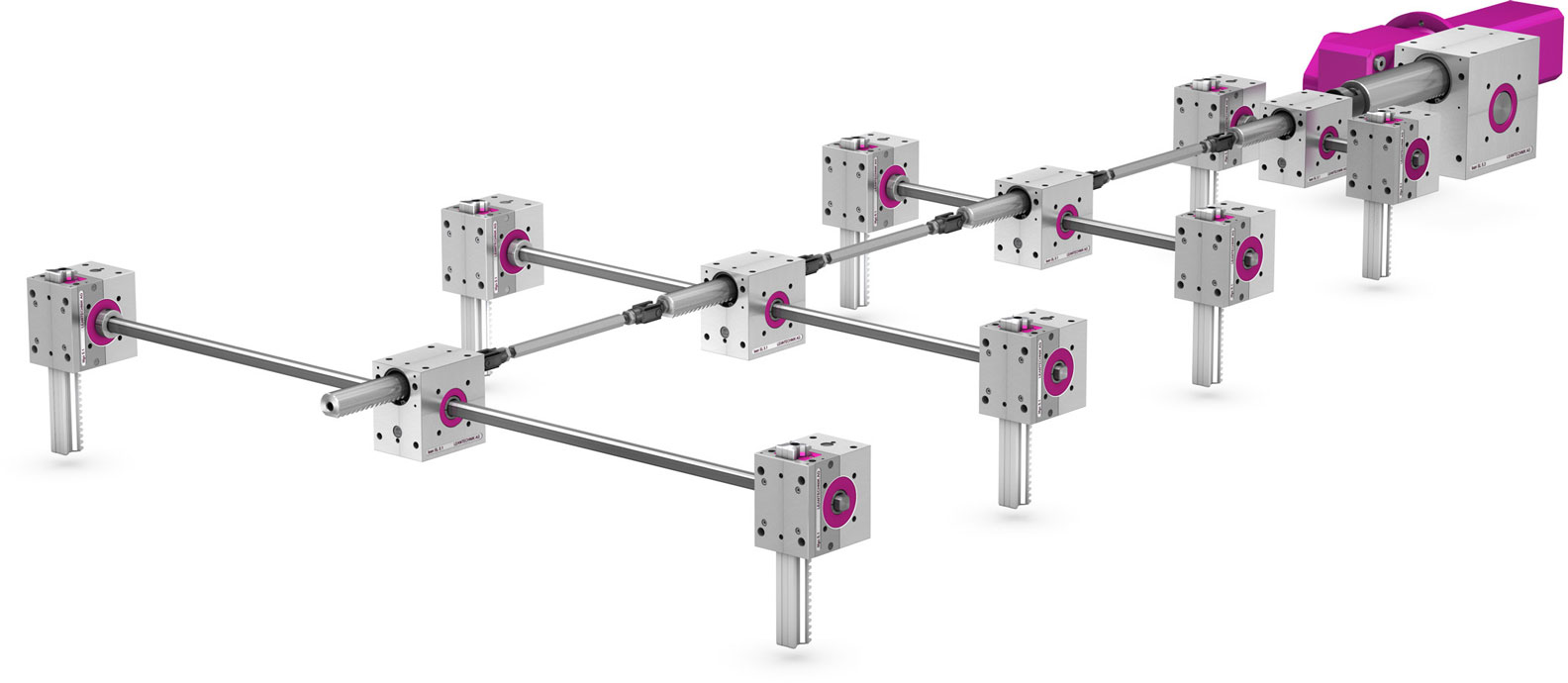

Lifting system with 3 primary gearboxes in series

The horizontal racks of the lean SL® primary gearboxes act as "tie rods" in this application, as do the differential clutches.

Standard lifting system with lifgo® and air cylinder drive

The two primary gear units of the lifgo® series each distribute half of the maximum possible force to the four gear units with vertical rack. The lifgo® racks guide overhead loads and can absorb lateral forces.

Lifting system with 3 primary gearboxes in series

The horizontal racks of the lean SL® primary gearboxes act as "tie rods" in this application, as do the differential clutches.

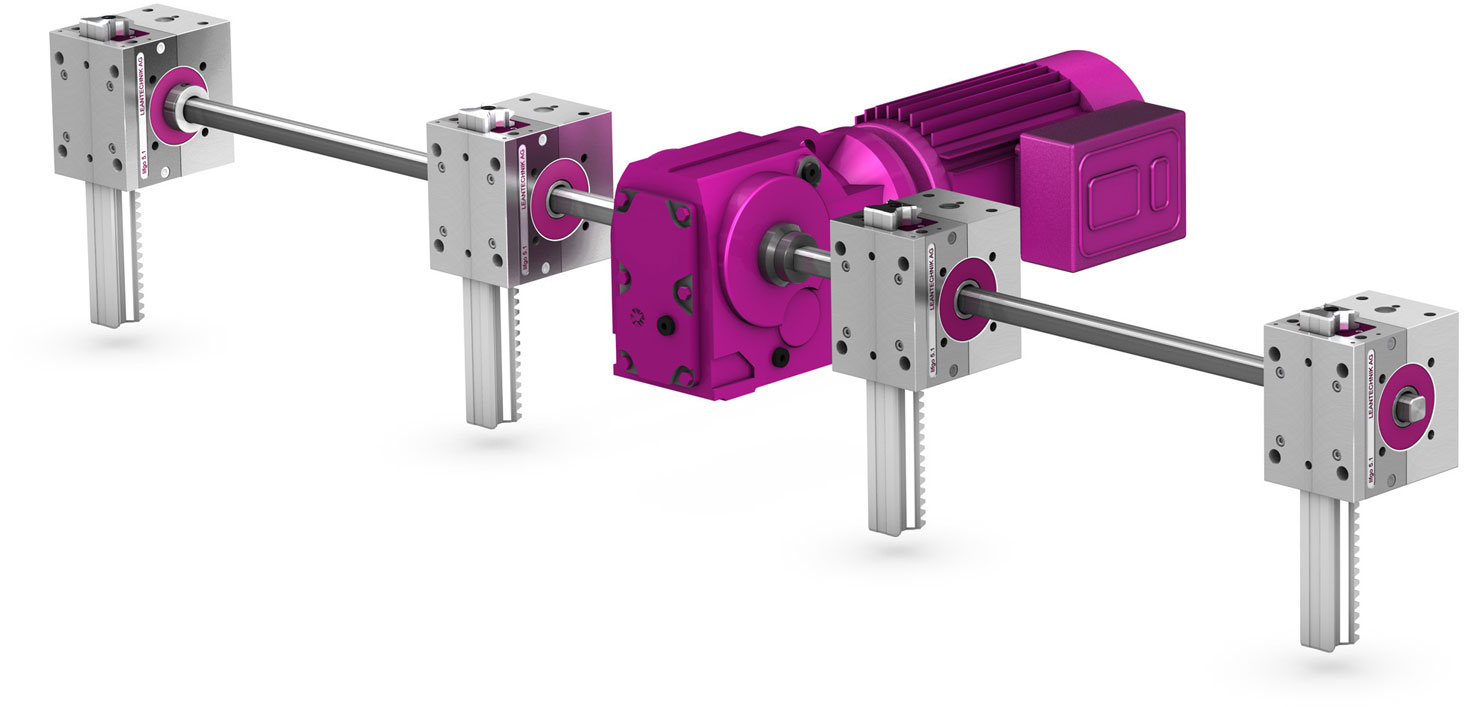

lifgo® lifting system in a row

Lifting system and device e.g. for lifting long parts and profiles. This application also corresponds to the vertical lift for a single-row shuttle.

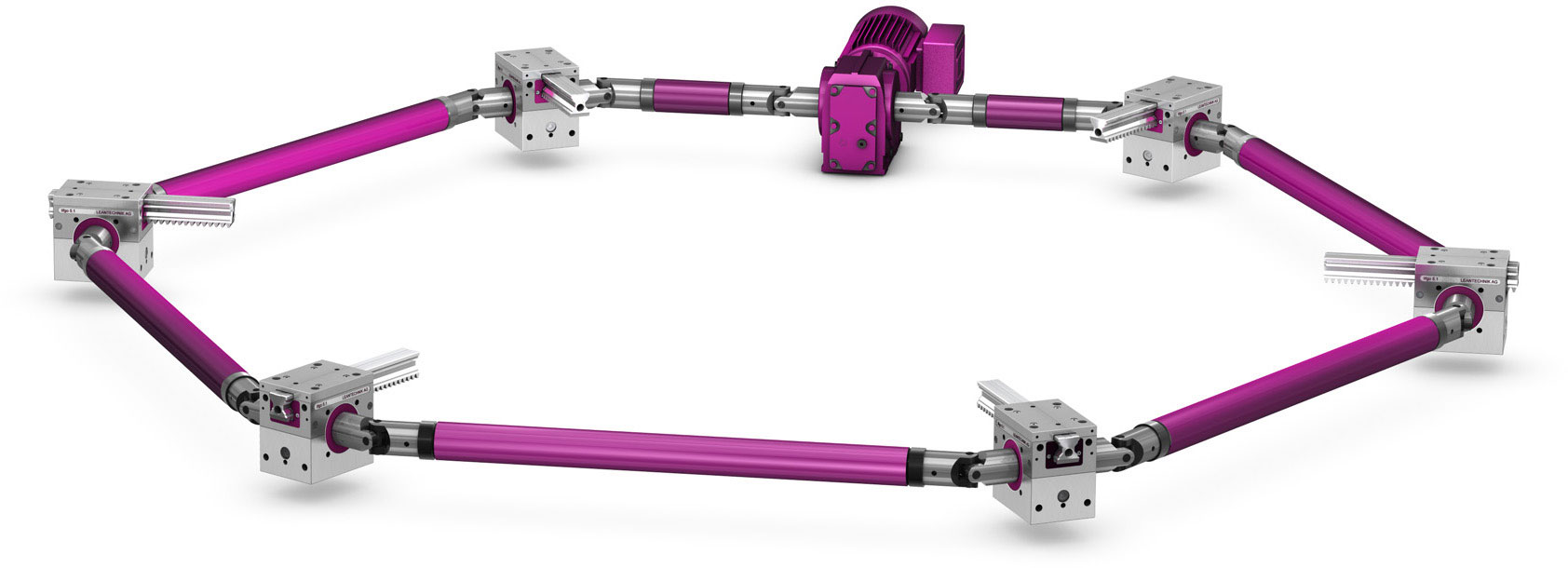

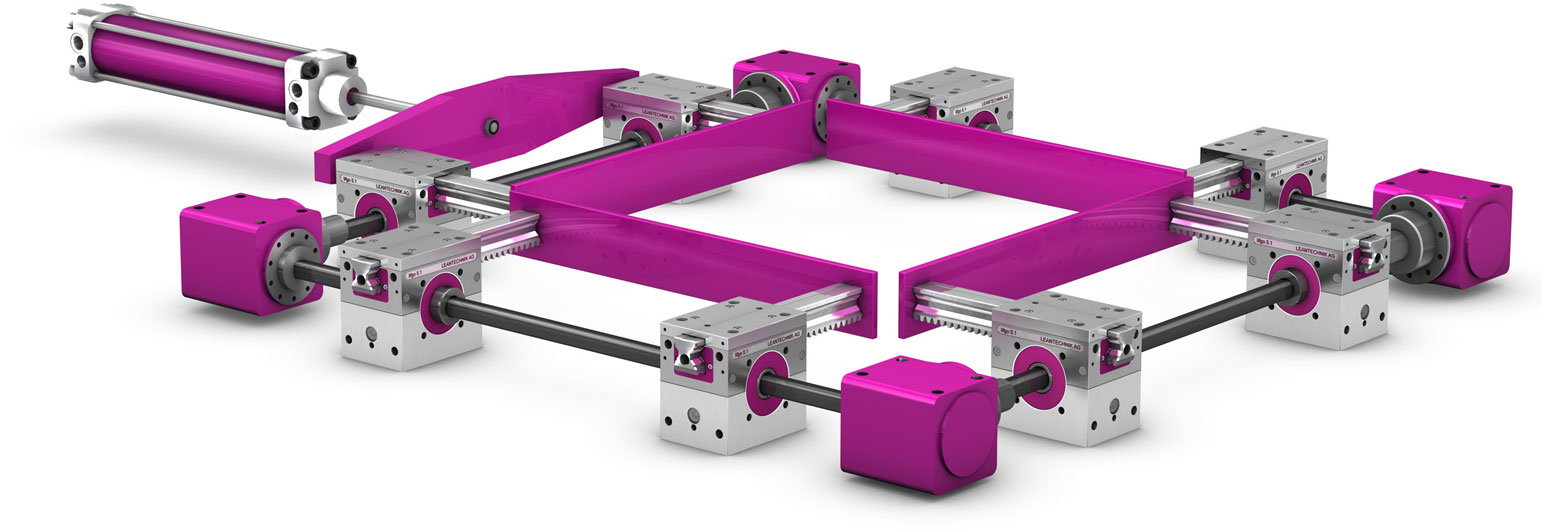

Circular installation of the lifgo® gearboxes

This lifgo® application can be used for clamping and/or centring round bodies. Closing round moulds (carcasses) is also a possible application.

lifgo® lifting system in a row

Lifting system and device e.g. for lifting long parts and profiles. This application also corresponds to the vertical lift for a single-row shuttle.

Circular installation of the lifgo® gearboxes

This lifgo® application can be used for clamping and/or centring round bodies. Closing round moulds (carcasses) is also a possible application.

Rectangle/square set-up

This application with gearboxes of the lifgo® series is used for clamping and/or centring.

Setting up gearboxes in four rows

Set-up as in the set-up of gearboxes in a row. In addition to the lean SL® gearboxes, lifgo® gearboxes are now set up on both sides, for example to lift wide, guided superstructure plates.

Rectangle/square set-up

This application with gearboxes of the lifgo® series is used for clamping and/or centring.

Setting up gearboxes in four rows

Set-up as in the set-up of gearboxes in a row. In addition to the lean SL® gearboxes, lifgo® gearboxes are now set up on both sides, for example to lift wide, guided superstructure plates.

Synchronous lifting systems – in action!

Lifting Tables

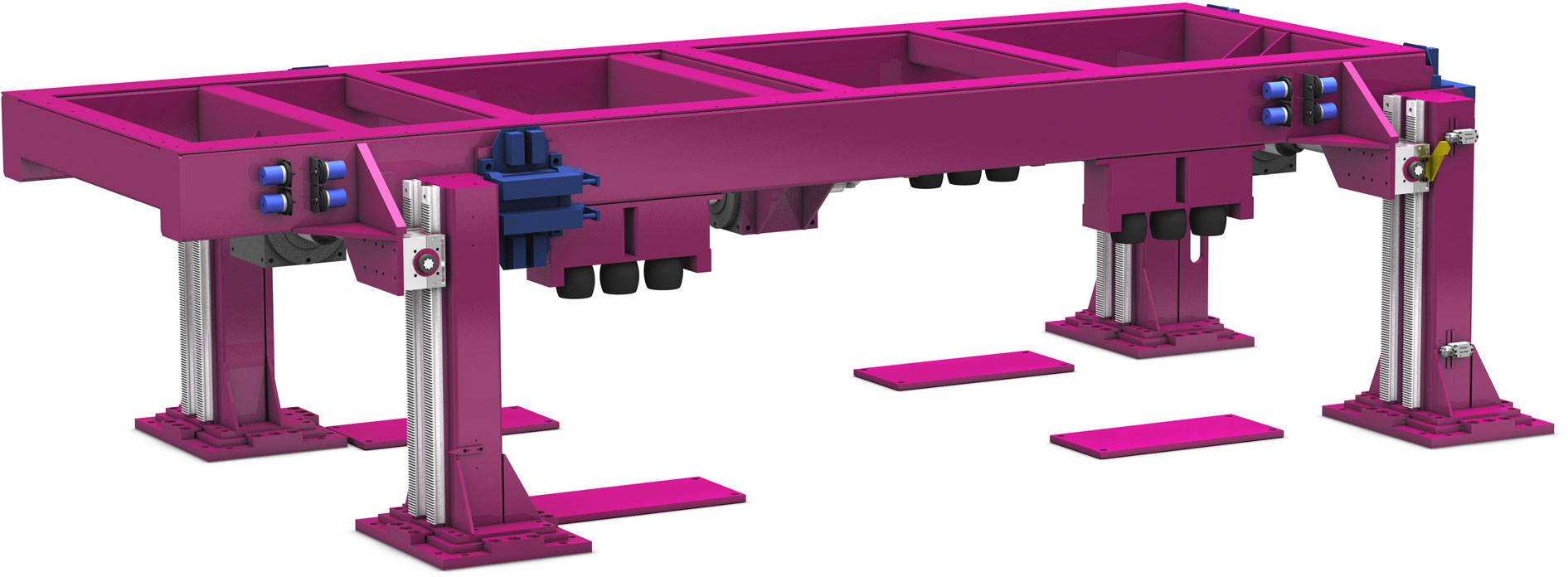

lean SL®-Lifting Table

Lifting table for high loads with high repeatability. Loose guidance to avoid over-definition, e.g. for centring tasks. The lifting table consists of two double columns with two lean SL® gearboxes each and can lift e.g. 1800 kg in the version shown with size 5.3 gearboxes.

lifgo® precision lifting table

Application for high loads with high positioning and repeat accuracy. Exact guidance and adherence to the position during the stroke is required. Additional equipment used here includes safety pin-offs, central lubrication and damping. Synchronisation is initiated via a central drive.

lean SL®-Lifting Table

Lifting table for high loads with high repeatability. Loose guidance to avoid over-definition, e.g. for centring tasks. The lifting table consists of two double columns with two lean SL® gearboxes each and can lift e.g. 1800 kg in the version shown with size 5.3 gearboxes.

lifgo® precision lifting table

Application for high loads with high positioning and repeat accuracy. Exact guidance and adherence to the position during the stroke is required. Additional equipment used here includes safety pin-offs, central lubrication and damping. Synchronisation is initiated via a central drive.

Lifting Tables – in action!

Lifting Columns

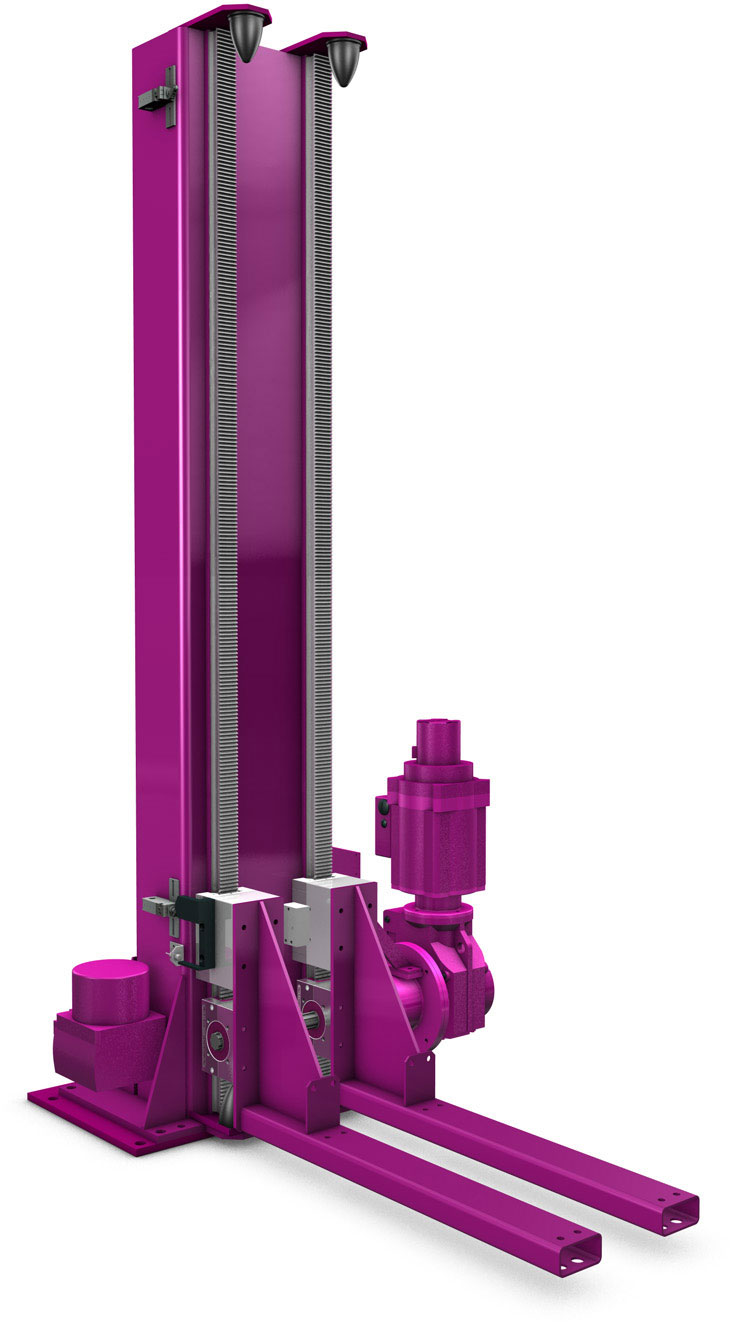

Lifting column with additional guide

Precise guidance for lifting operations with high and decentralised loads. The application enables high loads and a large lateral force absorption. It is suitable, for example, for the exact lifting and positioning of loads and production devices.

Lifting column – lifting device with two lifgo® linear and additional guide

Here, lifting forks are directly attached to lifgo® linear. Various purpose-built additional elements can be attached. Our lifting columns are also available with counterweights.

Lifting column with additional guide

Precise guidance for lifting operations with high and decentralised loads. The application enables high loads and a large lateral force absorption. It is suitable, for example, for the exact lifting and positioning of loads and production devices.

Lifting column – lifting device with two lifgo® linear and additional guide

Here, lifting forks are directly attached to lifgo® linear. Various purpose-built additional elements can be attached. Our lifting columns are also available with counterweights.

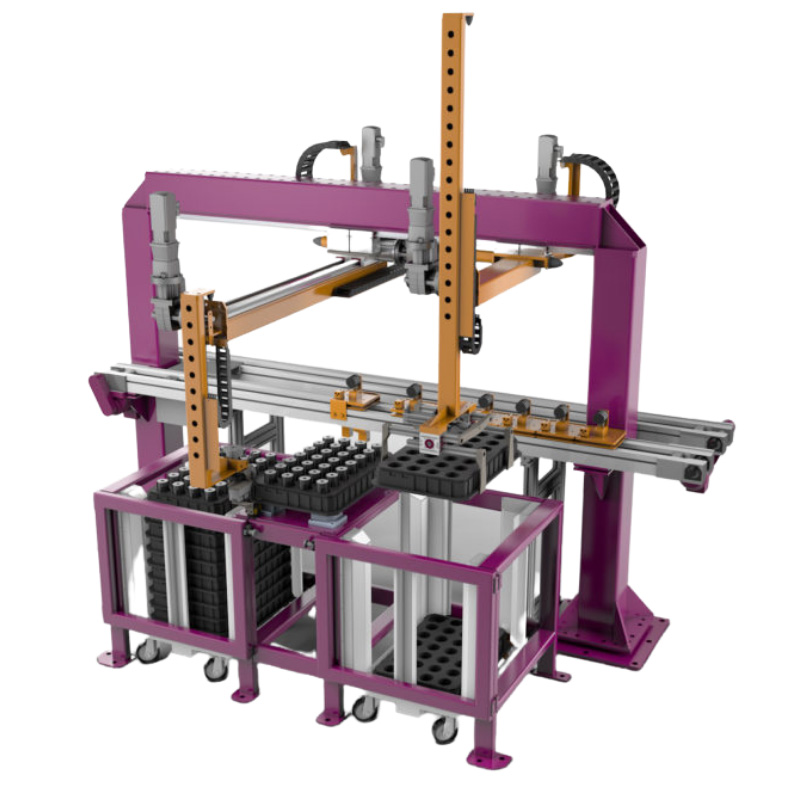

Lifting column as an intermediate stacker unit with a lifgo® linear

This application with a lifgo® linear is used for the intermediate storage of flat products on different levels.

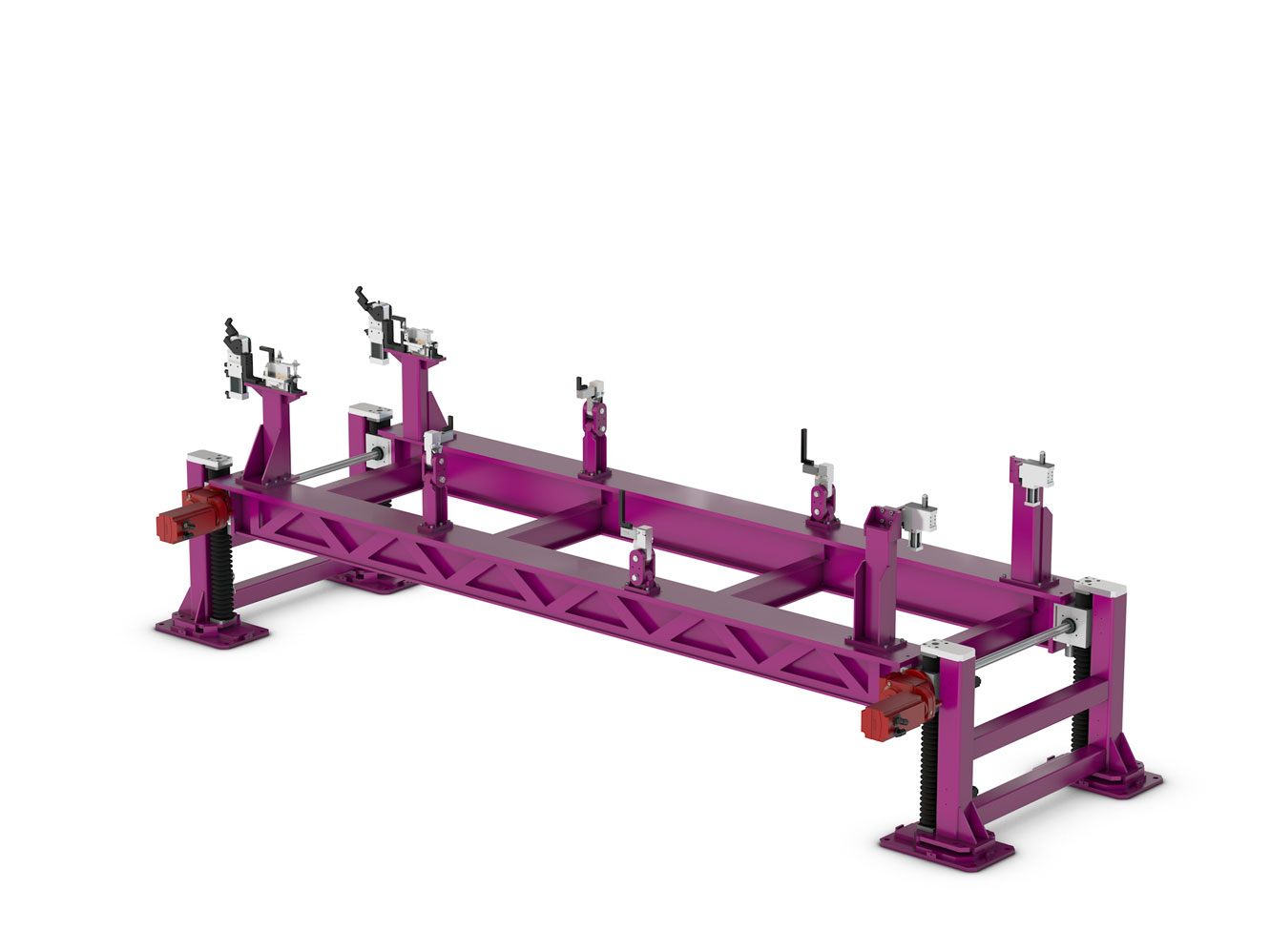

Lifting column with reinforcement profiles on the lifgo® linear gear rack

Lifting system in particularly bending-resistant design, for lifting heavy parts/fixtures in assembly lines, e.g. for final assembly of front axles with engine/transmission in the automotive industry. Large lifting heights, high lateral force absorption and positioning accuracy.

Lifting column as an intermediate stacker unit with a lifgo® linear

This application with a lifgo® linear is used for the intermediate storage of flat products on different levels.

Lifting column with reinforcement profiles on the lifgo® linear gear rack

Lifting system in particularly bending-resistant design, for lifting heavy parts/fixtures in assembly lines, e.g. for final assembly of front axles with engine/transmission in the automotive industry. Large lifting heights, high lateral force absorption and positioning accuracy.

Lifting Columns – in action!

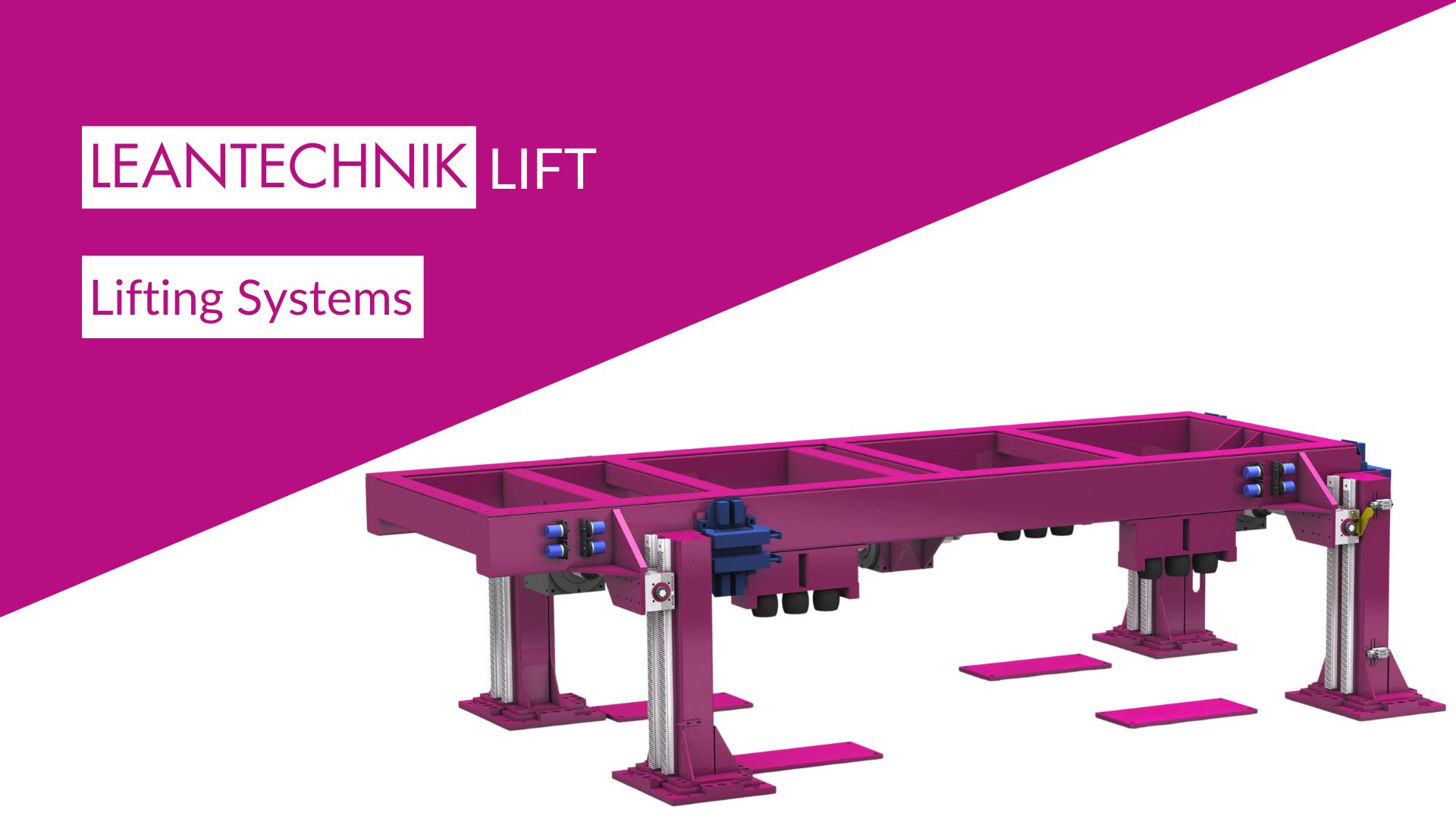

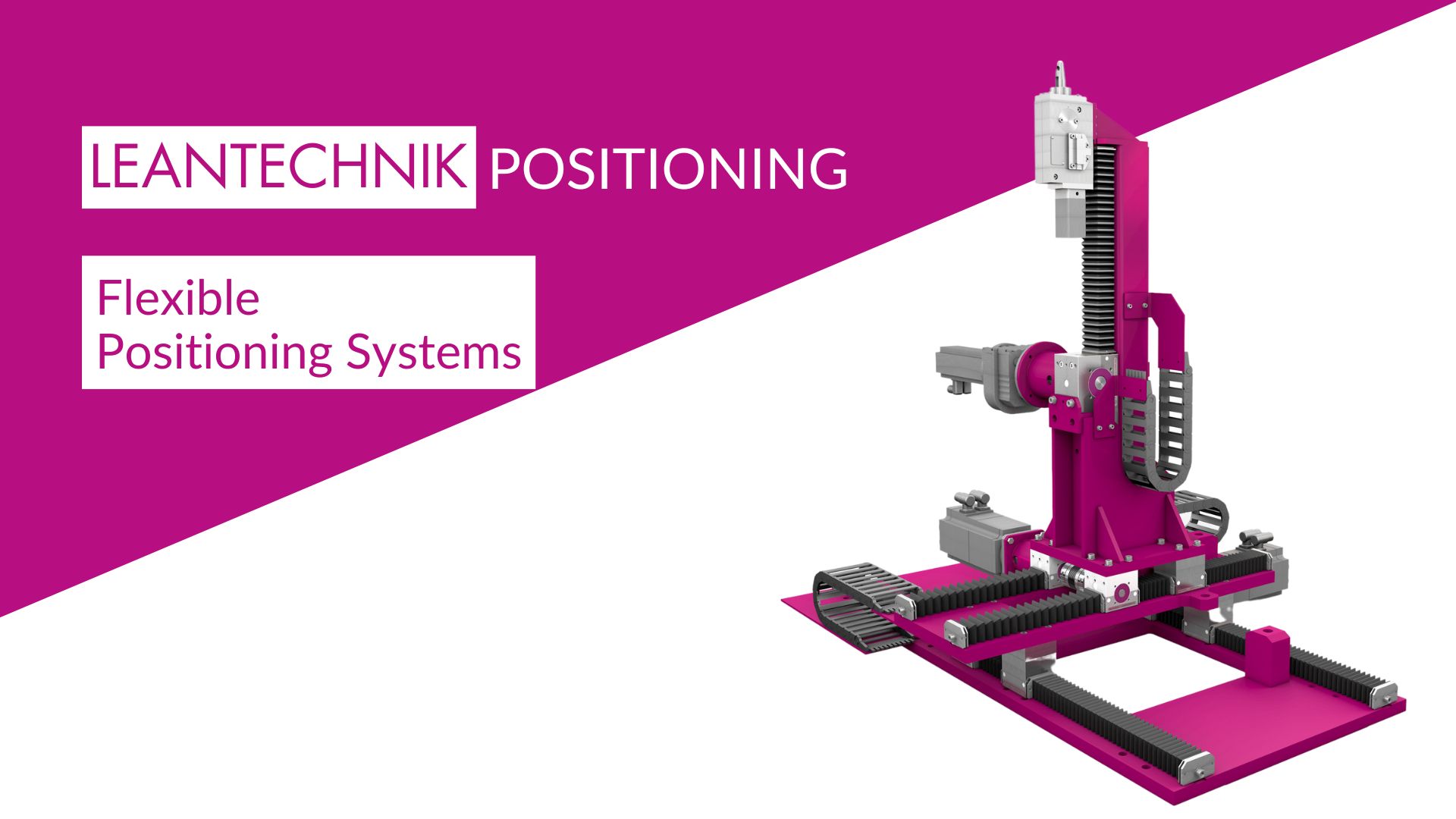

LEANTECHNIK SYSTEMS – Automation with SYSTEM

The LEANTECHNIK SYSTEMS product division refers to the development and design of partially and functionally ready plants & systems based on our lifgo® and lean SL® gearbox series.

Our motivation:

You provide the ideas – we provide the implementation!

At LEANTECHNIK SYSTEMS, we provide you with the complete know-how and implementation power of our design engineers. We accompany your project from the initial enquiry, through the complete design and planning of your system (incl. service life calculation), right up to implementation on your premises.

Discover:

Lifting Tables Lifting Columns Flexible Positioning Systems Pick & Place & & more possibilities

adapted to your needs!

Benefit from the many years of experience of our team of engineers, who are on hand to advise you in the areas of development and design. LEANTECHNIK SYSTEMS stands for customised solutions that are designed especially for you, so that they are precisely tailored to your needs.

LEANTECHNIK SYSTEMS - Discover the LEANTECHNIK system solutions & complete systems

With lifgo® and lean SL® we will find the perfect solution for your

the perfect solution for your specific case.

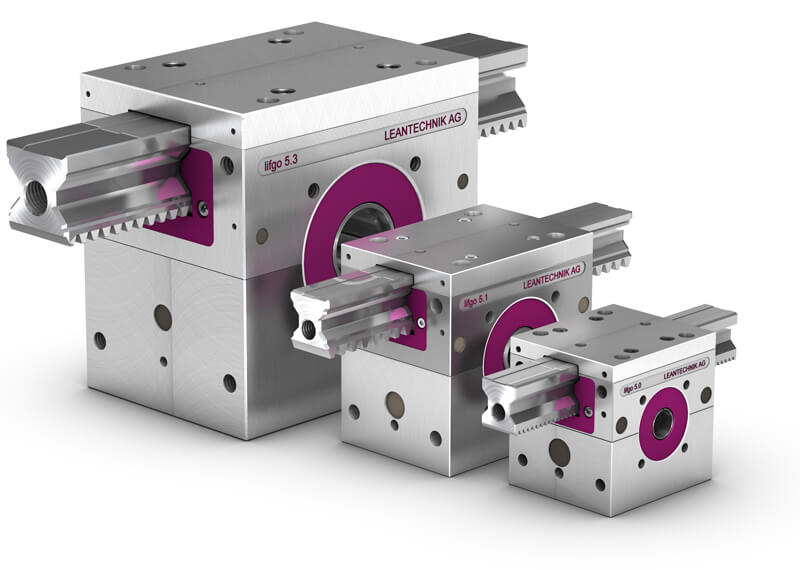

lifgo®

This linear-guided rack and pinion screw jack is suitable for fast, precise and synchronous installations. For applications requiring high lateral force absorption, our resilient and durable lifgo® series is the first choice.

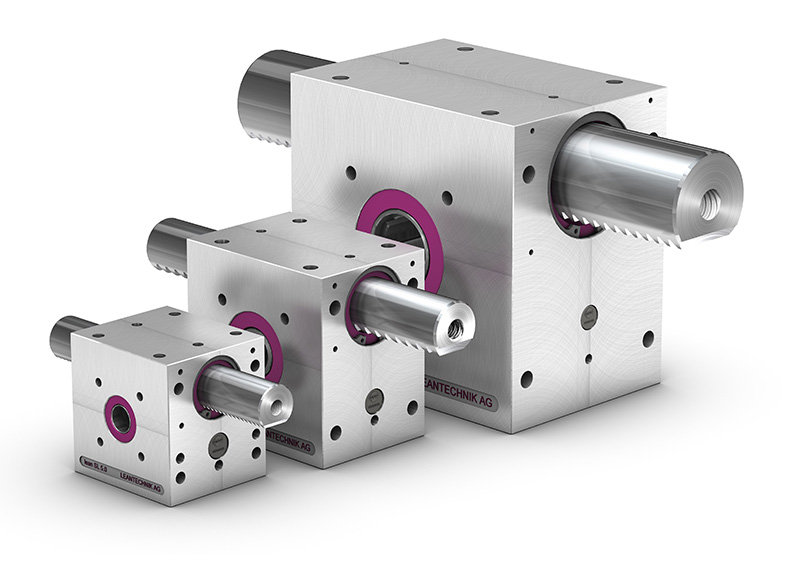

lean SL®

The robust and inexpensive alternative to the lifgo®. The gear unit is suitable for simple synchronous lifting tasks where an exact guide is already available and a transverse force absorption is not required.