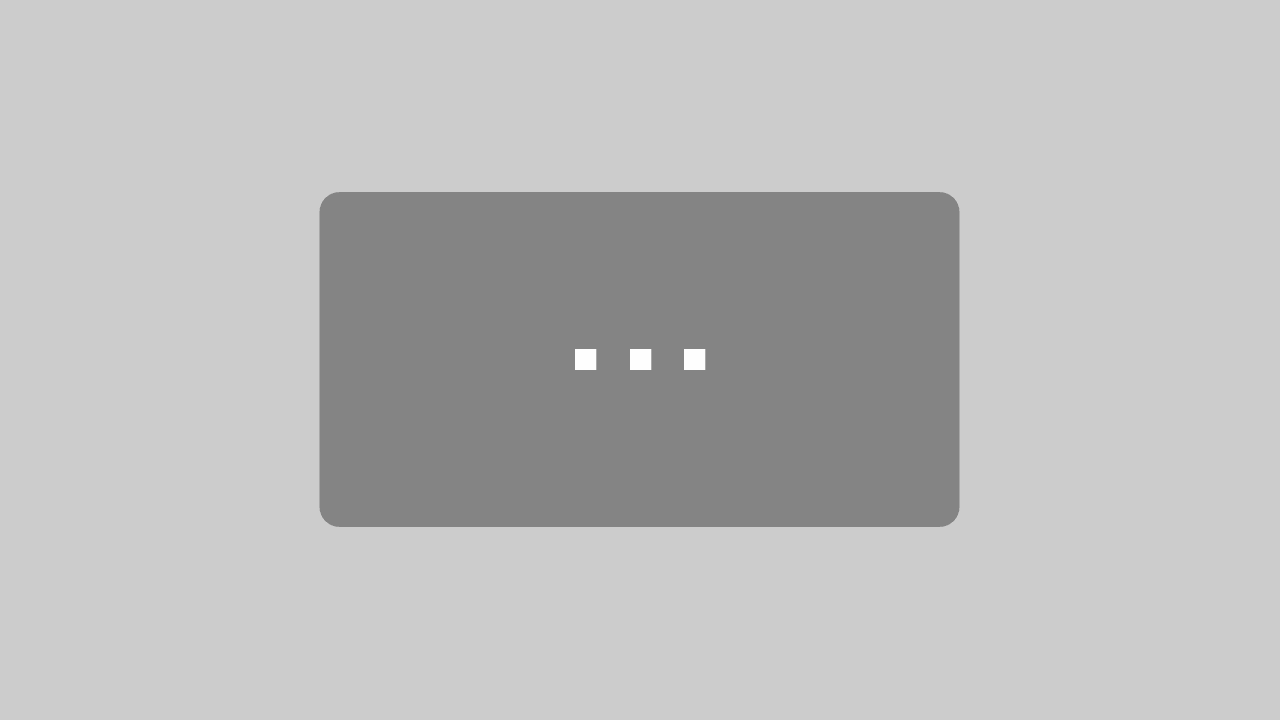

lifgo hp® – High Precision

Rethink Precision.

-

Extremely high precision (~ 2µm)

-

Highest gear quality

-

High stiffness independent of stroke

-

Compact design

-

Easy installation

-

Low maintenance

See our lifgo hp® in action!

lifgo hp® – Rethink Precision.

Revolutionise production with lifgo hp®: The infinitely adjustable rack-and-pinion gear for maximum precision and efficiency

An innovation in machine tool manufacturing

Until now, the length of the stroke was a limiting factor for many of the technologies used in the realisation of machine tools.

With the new lifgo hp® from LEANTECHNIK, these problems are a thing of the past.

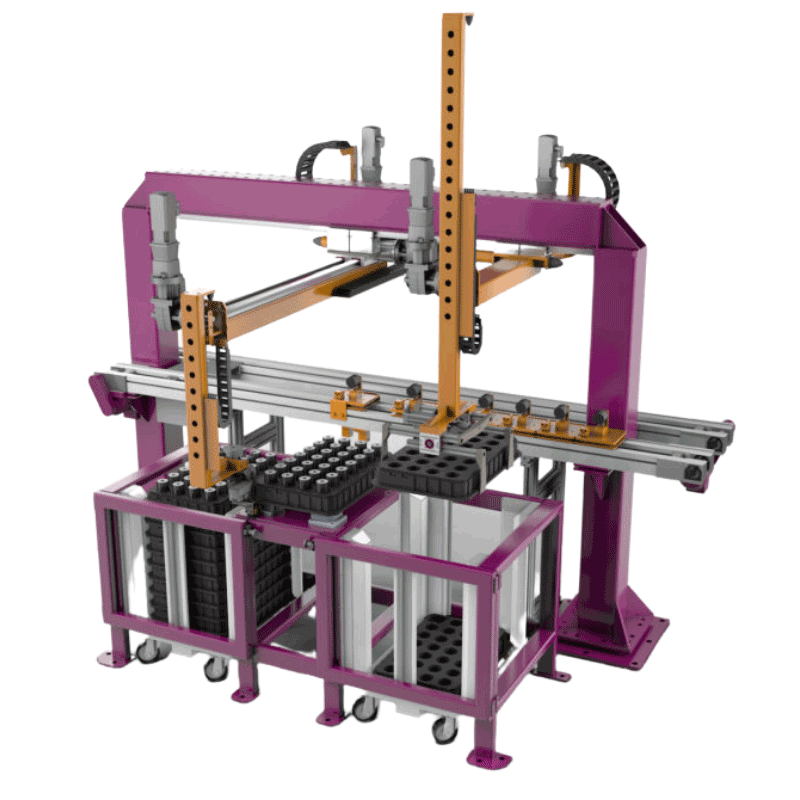

The lifgo hp® is used here as an example of machine tools.

However, it can be used in every conceivable industry and direction of travel (X/Y/Z axis) where extremely high precision is required.

Changing the status quo

More axes that have to be synchronised mean more installation work!

From a stroke of approx. 1500mm, the vibration of the components installed here can become increasingly greater. The accuracy suffers massively from this circumstance.

For long strokes, the diameter had to be increased so that sufficient rigidity could be achieved – at the expense of dynamics.

The use of the lifgo hp® creates a new definition of precision in combination with a simplification of synchronisation and assembly.

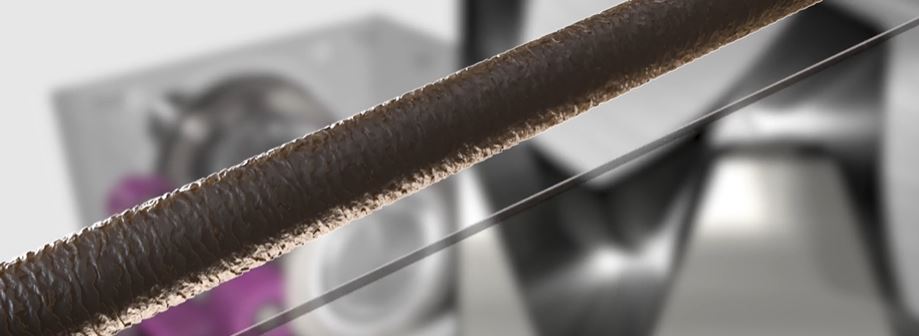

Extremely high precision ~ up to 2µm

(2/1000 mm)

Precision down to the last detail!

The accuracy corresponds to up to 2/1000 mm.

Approximately the fraction of a human hair.

With the lifgo hp®, you position extremly precise.

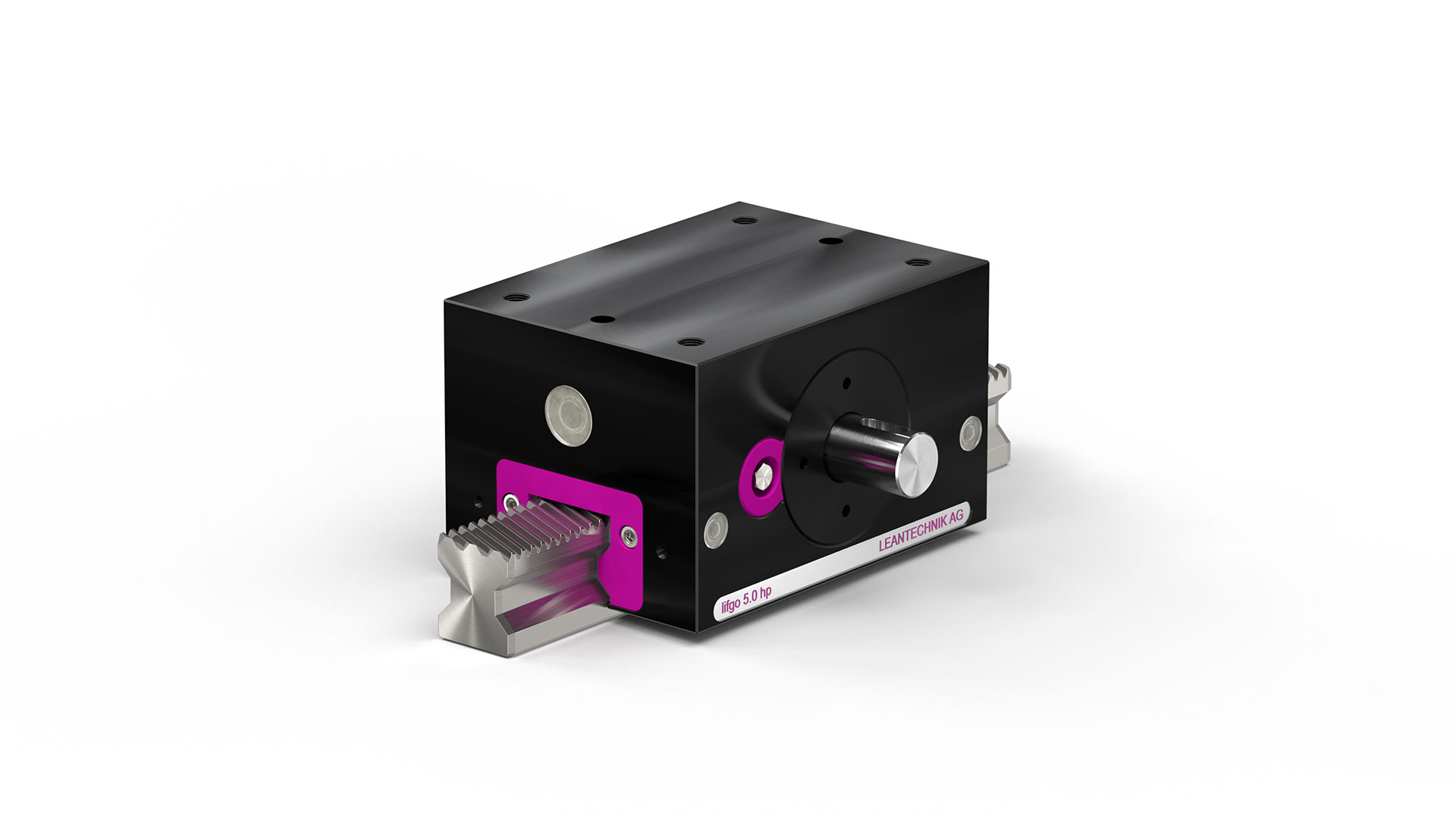

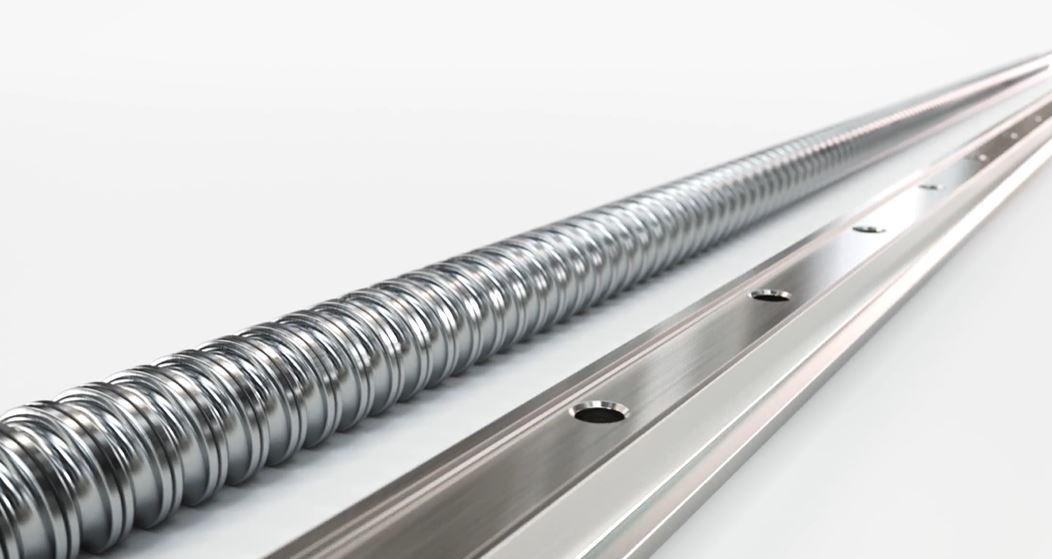

Highest gearing quality

Extremely precise and smooth running due to its helical gearing.

The rack teeth of the lifgo hp® are helical for particularly smooth running and precision.

Your advantages with helical toothing:

Load capacity

Helical gearing makes it possible to operate the rack and pinion gears with an even load. The load distribution across the tooth width is even and the service life of the gearbox is extended.

Efficiency

The helical gearing produces smooth running of the gears. Friction and heat generation are reduced. This leads to a higher power throughput of the gearboxes.

Noise reduction

Helical gearing can also help reduce noise levels compared to straight gearing. This is especially important when the gearbox is used in noise-sensitive environments or when strict noise level regulations have to be met.

Maximise your productivity with lifgo hp®!

Our ultra-modern rack-and-pinion gear with infinitely adjustable backlash offers you unsurpassed precision and efficiency.

Say goodbye to poor production results and discover the advantages of our innovative product.

Take your production to a new level!

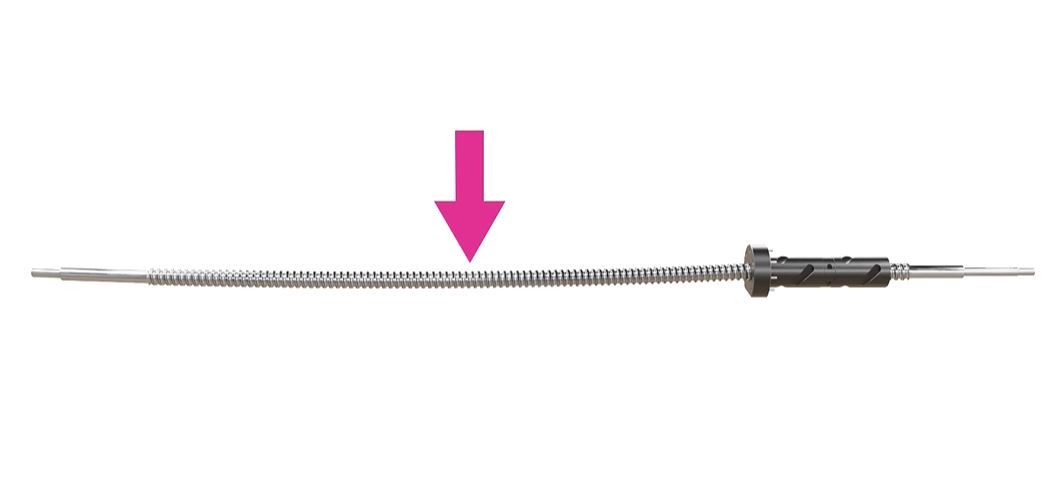

High stiffness – independent of stroke

The longer the stroke – the more vibration in the system.

Until now, the length of the stroke has been a limiting factor for many of the technologies used in the realisation of machine tools.

From approx. 1.50 m stroke, the vibrations of the installed components become greater and the accuracy increasingly suffers. For long strokes, the diameter of the KRS is increased so that sufficient stiffness can be generated – at the expense of dynamics.

With the new lifgo hp® from LEANTECHNIK, these problems are a thing of the past.

The stiffness in the system remains high, regardless of the stroke.

Your advantages of high stiffness in the machine:

Precision

A high degree of rigidity in machine tools makes it possible to maintain the tool-workpiece position precisely and thus achieve greater precision in machining. This is particularly important in demanding applications such as the production of precision parts.

Productivity

High rigidity in machine tools leads to less deformation under load, which increases productivity.

Longevity

High rigidity in machine tools reduces the loads on the machine parts and tools, resulting in a longer service life. This reduces the costs for maintenance and spare parts and increases the availability of the machine.

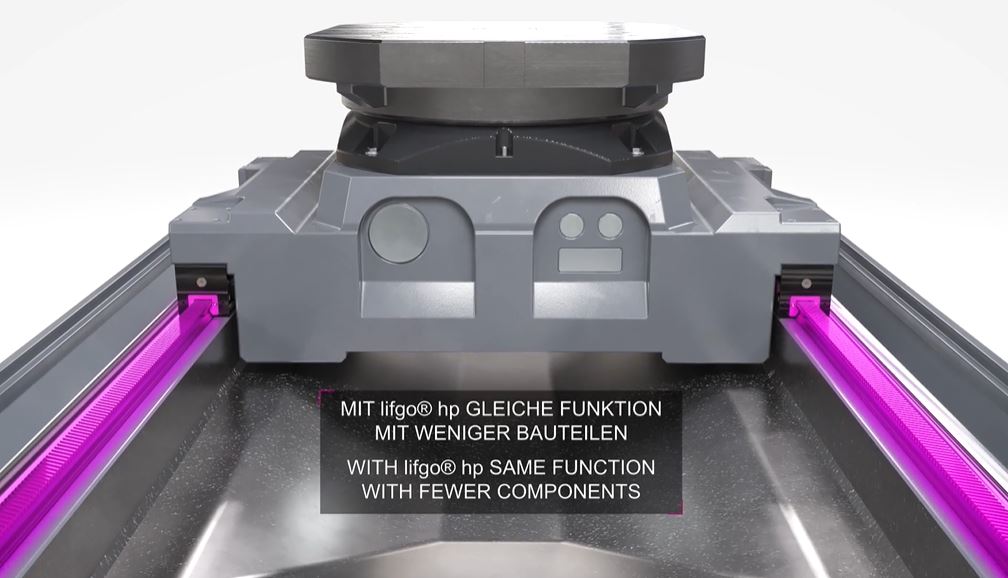

Compact design

Saving space – made easy.

Four axes in the system mean a higher demand for installation space and assembly.

Why not combine the gear and the guide in one component?

Your advantages due to the compact design of our gearboxes:

Saving space

A very compact design of rack and pinion gear units saves valuable space in plants and machines as they have a smaller footprint than other drive systems.

Lighter weights & dimensions

Compact rack and pinion gear units usually have lower weights than other drive systems, which leads to improved manageability and easier integration into existing plants.

Easy maintenance

A compact design in rack and pinion gearboxes allows easier access to the moving parts, which enables faster and easier maintenance. In addition, a compact design reduces the risk of damage from shock or vibration.

Fusion of gearbox & guide

Gearbox & guide in ONE SYSTEM

The lifgo hp® combines these two features in one system and not only saves the user installation space but also reduces the maintenance and installation effort at the same time.

Your advantages through the combination of gearbox & guide in one system:

Improved efficiency

Combining gearbox nd guide in one system increases efficiency in machines by minimising losses due to transmission and friction.

Reduction of costs

Integrating the gearbox and guide into one system reduces costs for procurement, assembly and maintenance, as fewer parts are required and the overall system is easier to install and maintain. Cost degression through the entire value chain.

Reduced number of components

By combining the gearbox and guide in one system, the number of components required is reduced, resulting in simplified design and fewer failures due to component failure. In addition, the reduction in the number of components allows for improved adjustment and overview and easier monitoring of the system.

Steplessly adjustable

The adjustment of the backlash is infinitely adjustable.

You can adjust the tooth backlash on the lifgo hp® steplessly and individually with the help of a key.

The effort is also low, as it is adjusted centrally.

Your advantages due to our infinitely adjustable tooth backlash:

Precision & Performance

With a continuously adjustable tooth backlash, the clearance between the tool and the workpiece can be precisely adjusted, resulting in higher accuracy and tolerance during machining.

A continuously adjustable tooth backlash makes it possible to optimise the performance of the machine.

Wear reduction & longevity

Infinitely adjustable tooth backlash helps reduce wear on tools and machine parts by minimising friction and loads.

Precise adjustment of the backlash can increase the service life of the tools and machine parts.

Reduction of costs

The service life of the tools and machine parts is increased, thus reducing costs for maintenance and spare parts.

Maximise your productivity with lifgo hp®!

lifgo hp® – Technical data

Download the technical data for the lifgo hp® now.

Information on further products can be found in our complete catalogue.

Our sales team will be happy to advise you!

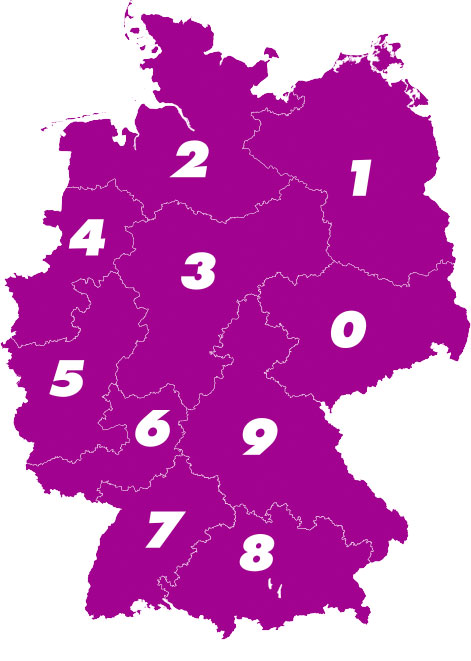

Our sales staff are at your disposal at any time for a non-binding consultation at your premises. To get in touch with your contact person, take a look at who is responsible in your postcode area.

While our product development and design takes place in Oberhausen, our sales staff is at your disposal throughout Germany.

Excellent customer care is part of our understanding of service.

You can find your suitable contact person here:

Head of Sales

Field Service

Sales Manager (international)

ANDREAS SPRENGER

E-Mail: sprenger@leantechnik.com

Phone: +49 208 495 25 65

Mobile: +49 151 57 123 640

MORITZ KNUPLESCH

E-Mail: knuplesch@leantechnik.com

Phone: +49 208 495 25 60

Mobile: +49 151 160 425 84

Key Account Management

Global Key Account Manager

JULIAN BAUKNECHT

E-Mail: bauknecht@leantechnik.com

Telefon: +49 151 527 819 26

Global Key Account Manager

FRIEDRICH KLAEGER

E-Mail: klaeger@leantechnik.com

Telefon: +49 151 647 528 89

Inside Sales

ZIP-Area 0 | 1 | 4 | 5

AMNON SCHÜßLER

E-Mail: schuessler@leantechnik.com

Phone: +49 (0)208 495 25 99

Get in touch

Get your individual quote for the lifgo hp®.

LEANTECHNIK SYSTEMS - Automation with a SYSTEM

The LEANTECHNIK SYSTEMS product division refers to the development and design of partially and functionally ready plants & systems based on our lifgo® and lean SL® gearbox series.

Our motivation:

You provide the ideas – we provide the implementation!

At LEANTECHNIK SYSTEMS, we provide you with the complete know-how and implementation power of our design engineers. We accompany your project from the initial enquiry, through the complete design and planning of your system (incl. service life calculation), right up to implementation on your premises.

Discover:

Lifting Tables Lifting Columns Flexible Positioning Systems Pick & Place & more possibilities

adapted to your needs!

Benefit from the many years of experience of our team of engineers, who are on hand to advise you in the areas of development and design. LEANTECHNIK SYSTEMS stands for customised solutions that are designed especially for you, so that they are precisely tailored to your needs.