Lifting table meets skid conveyor

New lift- and carry unit of LEANTECHNIK

High Speed

Highest Precision

Low Maintenance

Flexible design

Simple Installation

See our Lift- and carry unit in action!

Lift-sink conveyor especially for your assembly

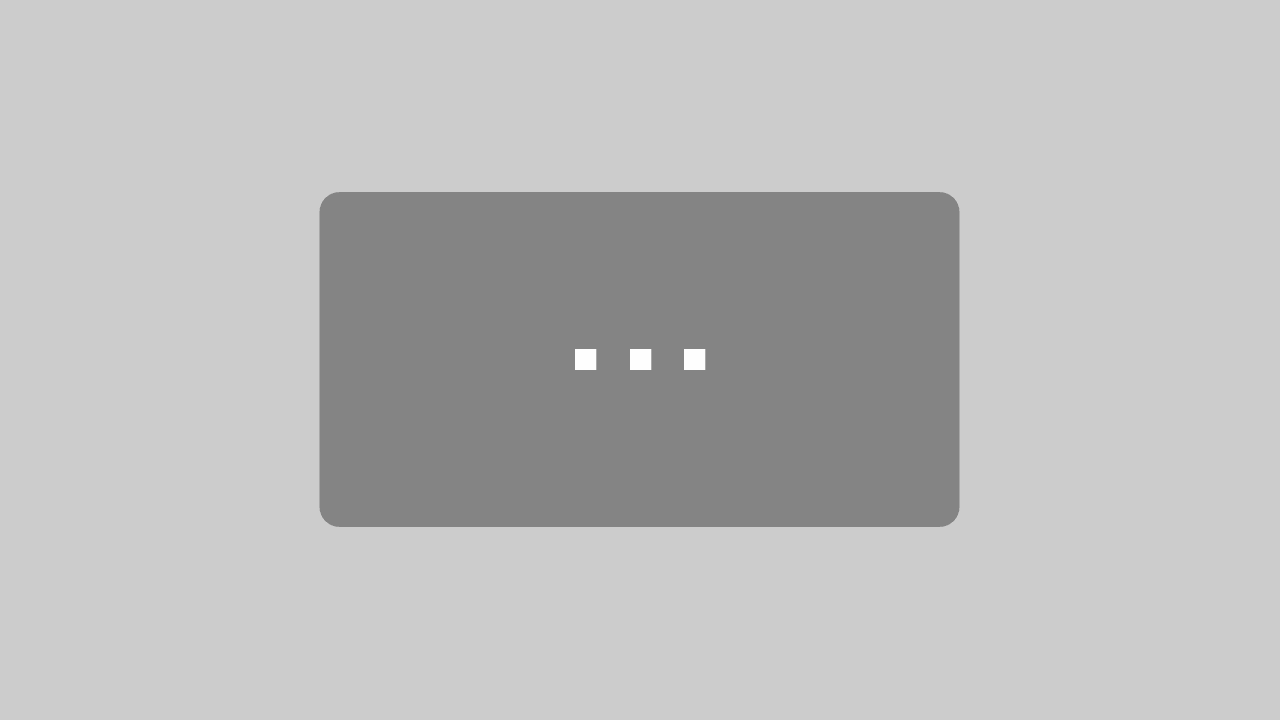

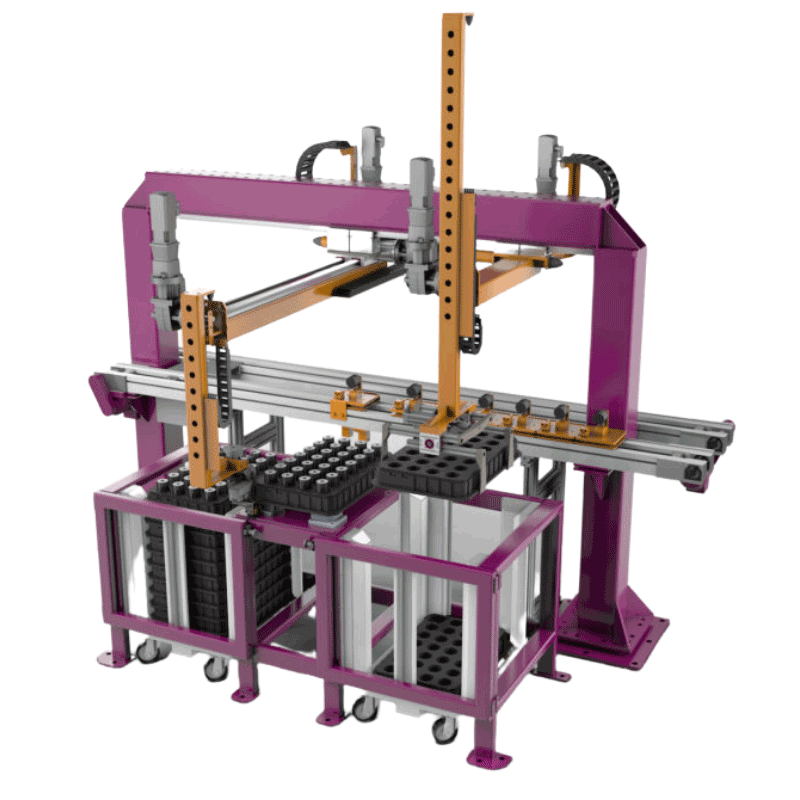

For automotive engineering, you need precisely fitting lifting and conveying technology that works quickly and with millimetre accuracy? An ideal solution is offered by the Lift- and carry unit exhibited at Automatica, which we have developed in cooperation with Bleichert Automation.

Lifting table meets skid conveyor

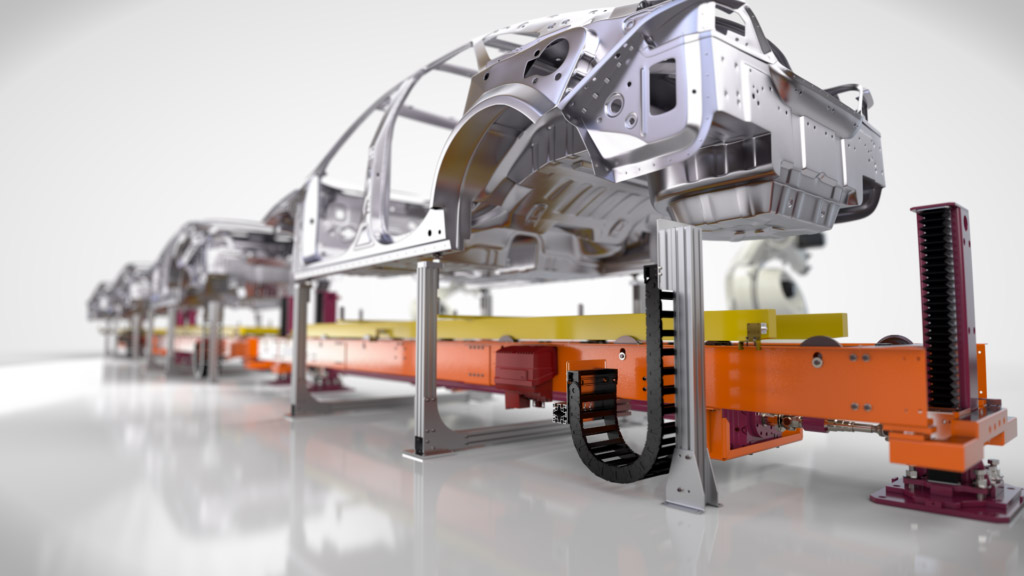

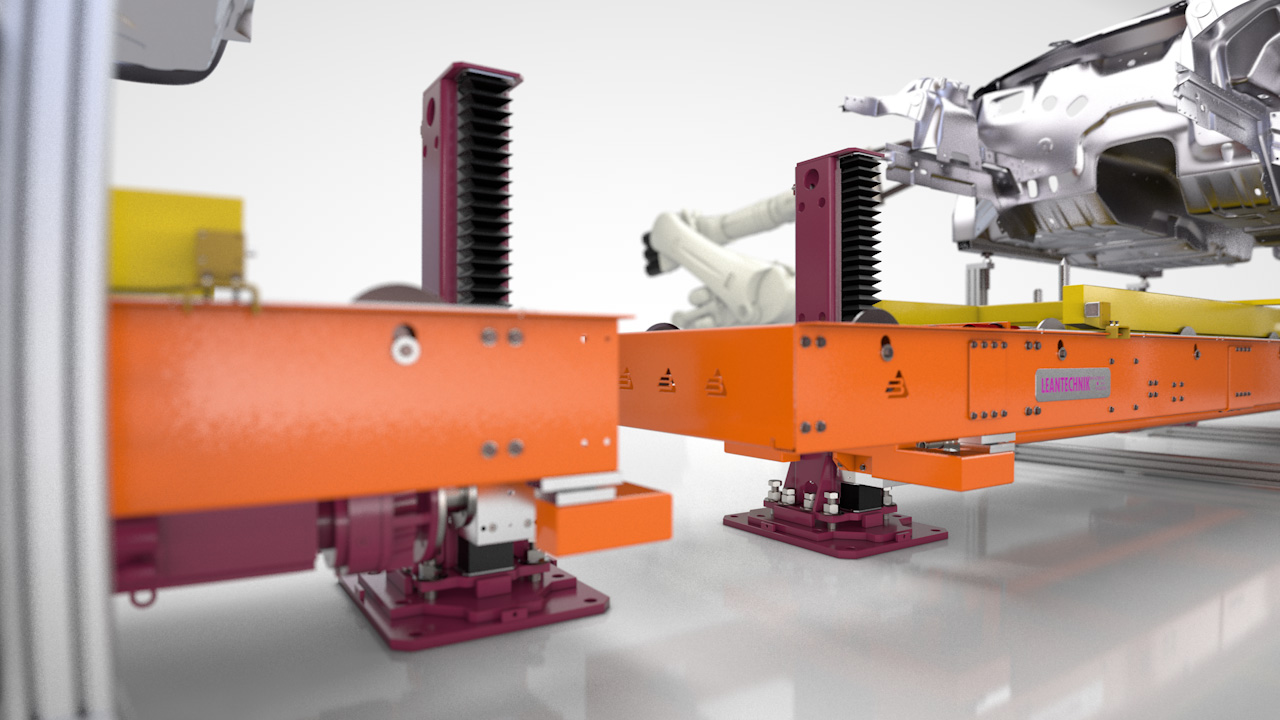

In order to transport car bodies as efficiently as possible, we combine a skid system with two of our lifting columns in the lifting/lowering conveyor. The design lowers, lifts and conveys heavy loads – and not only in automotive engineering.

High Precision

The lifting/lowering conveyor works extremely precisely and positions car bodies with repeatable accuracy.

High Speed

With its compact design, the lifting and lowering conveyor moves components in a matter of seconds.

Flexible Design

The slim steel construction of the lift- and carry unit can be designed flexibly and saves space.

LEANTECHNIK manufactures the lifting and lowering conveyor for you, adapted to your needs. To ensure this, we have defined our processes – from initial customer contact to after-sales service – through our quality management system and have them certified to ISO 9001.

Benefit from our experienced engineering team.

They are prepared to assist with design and development recommendations of cutting-edge solutions that meet your demands and requirements.

Check out our LEANTECHNIK SYSTEMS projects and find further information in our full catalogue.

Lifting. Lowering. Conveying – in perfect harmony.

Maximum load of the roller conveyor 750 kg

Conveying distance 6,500 mm horizontal and 650 mm vertical

Station change 8 s

Conveying height 600 mm

Our sales team will be happy to advise you!

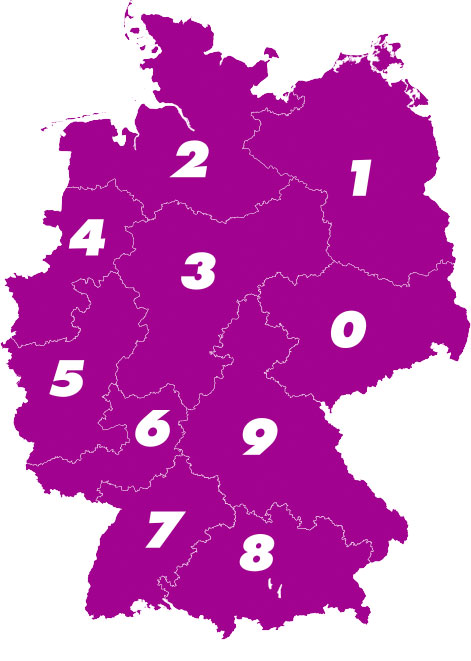

Our sales staff are at your disposal at any time for a non-binding consultation at your premises. To get in touch with your contact person, take a look at who is responsible in your postcode area.

While our product development and design takes place in Oberhausen, our sales staff is at your disposal throughout Germany.

Excellent customer care is part of our understanding of service.

You can find your suitable contact person here:

Chief Sales Officer (CSO)

Field Service

Sales Manager (international)

ANDREAS SPRENGER

E-Mail: sprenger@leantechnik.com

Phone: +49 208 495 25 65

Mobile: +49 151 57 123 640

MORITZ KNUPLESCH

E-Mail: knuplesch@leantechnik.com

Phone: +49 208 495 25 60

Mobile: +49 151 160 425 84

Key Account Management

Global Key Account Manager

JULIAN BAUKNECHT

E-Mail: bauknecht@leantechnik.com

Telefon: +49 151 527 819 26

Global Key Account Manager

FRIEDRICH KLAEGER

E-Mail: klaeger@leantechnik.com

Telefon: +49 151 647 528 89

Inside Sales

ZIP-Area 0 | 1 | 4 | 5

AMNON SCHÜßLER

E-Mail: schuessler@leantechnik.com

Phone: +49 (0)208 495 25 99

LEANTECHNIK SYSTEMS - Automation with a SYSTEM

The LEANTECHNIK SYSTEMS product division refers to the development and design of partially and functionally ready plants & systems based on our lifgo® and lean SL® gearbox series.

Our motivation:

You provide the ideas – we provide the implementation!

At LEANTECHNIK SYSTEMS, we provide you with the complete know-how and implementation power of our design engineers. We accompany your project from the initial enquiry, through the complete design and planning of your system (incl. service life calculation), right up to implementation on your premises.

Discover:

Lifting Tables Lifting Columns Flexible Positioning Systems Pick & Place & more possibilities

adapted to your needs!

Benefit from the many years of experience of our team of engineers, who are on hand to advise you in the areas of development and design. LEANTECHNIK SYSTEMS stands for customised solutions that are designed especially for you, so that they are precisely tailored to your needs.