Our solutions for the Packaging Industry

Our gearboxes increase produtivity and efficiency for your production facilities.

Reduction of costs

More competitiveness

High Flexibility

Increased Productivity

Easy mounting

LEANTECHNIK supports you with intelligent solutions along the entire production line – regardless of your company size.

The added value extends across all production processes and is specifically tailored to each task and phase.

Whether in front-of-line systems, during processing, transfer and positioning, or even in end-of-line applications, you can rely on our durable, low-maintenance, and space-saving products.

See our products in action!

Your benefits:

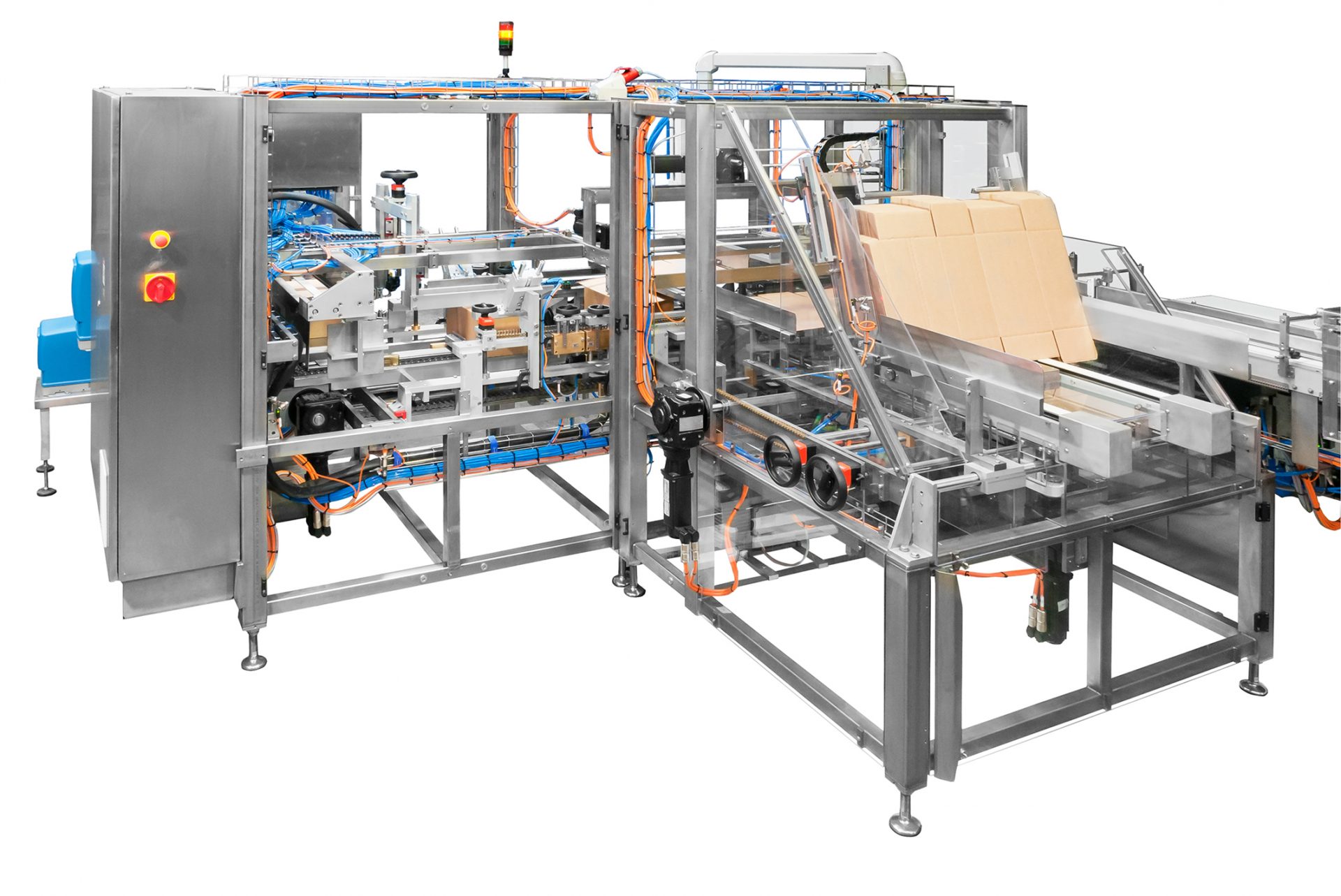

Application: Wrap Around / Tray Packer

The wrap-around/tray packer of a major machine manufacturer is a packaging multi-talent.

It packs sensitive foodstuffs such as butter and margarine for further transport and at the same time provides retailers with a corresponding sales display with the stable outer packaging. A lifgo® 5.1 linear gearbox ensures the precision required for packaging at high speed and high cycle times.

Application: Feeding unit for candle production

The two lifgo® rack and pinion gear units move the feed unit, which conveys the candles to the filling station (grid bottom) and then to the cooling section. The long stroke of the feed unit was a challenge for the machine builder’s designers.

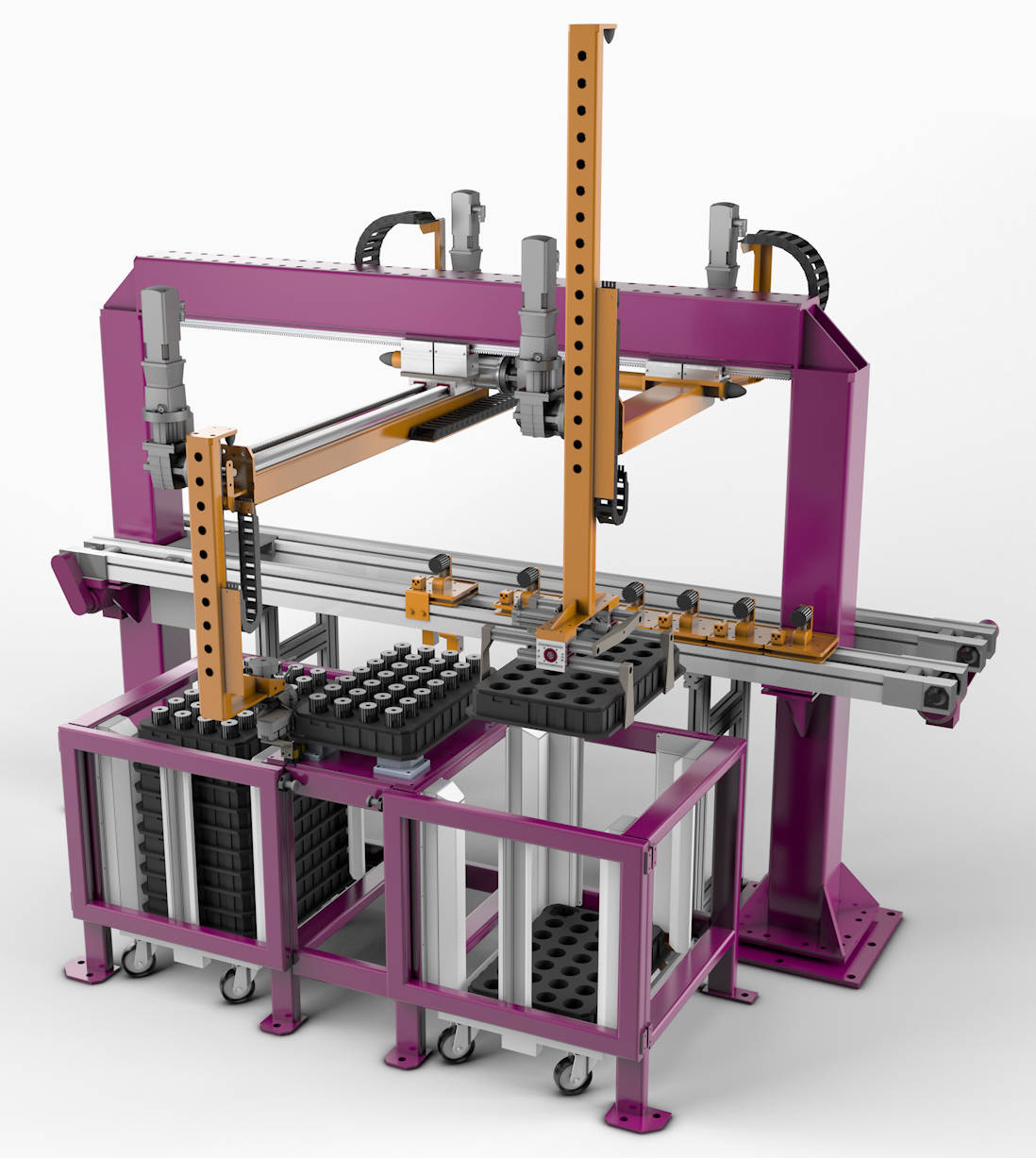

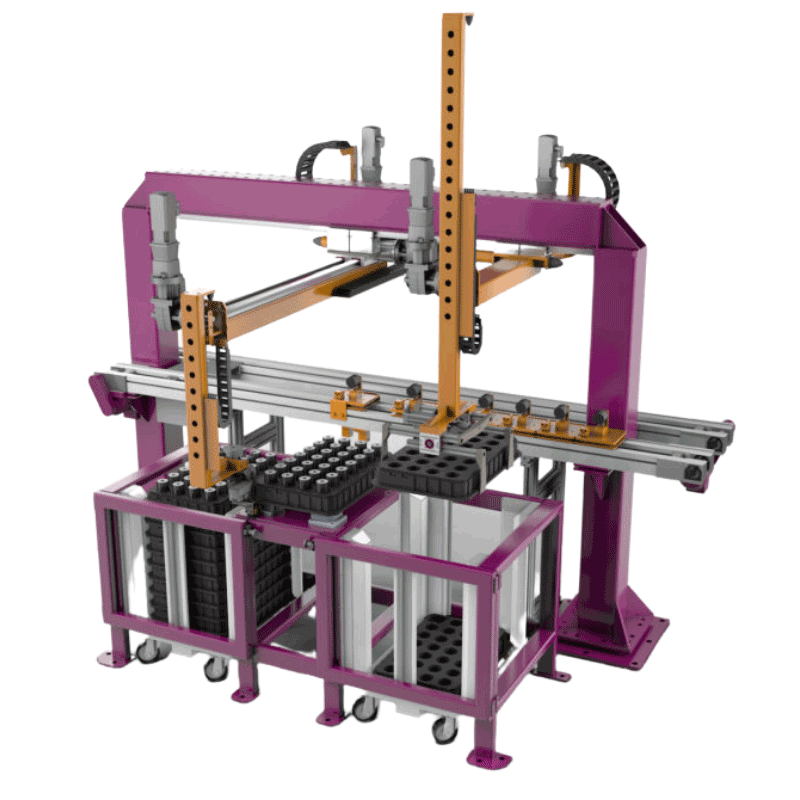

Application: Palletizer

The task: To first process technical blanks within a processing station before the finished parts placed in blisters are palletized.

For the processing, the raw parts are brought from the blister into a corresponding station by placing them on a conveyor belt.

Afterwards, the finished parts are to be removed from the conveyor at the same point and placed back into the blister. Finally, the blisters are palletized in the next step.

Application: Lifting column for quality inspection & final packing

The lifting column shown is used in the quality inspection of ceiling supply units.

Following the quality inspection, the ceiling supply unit is positioned in a specially manufactured final packaging with the help of the lifting column.

You need more information?

Benefit from the many years of experience of our engineering team, which is available to advise you in the area of development and design. leanSYSTEMS stands for tailor-made solutions that are designed especially for you, so that they are precisely adapted to your needs.

You can find more information about our products in our complete catalog.

What our customers say …

“The lifgo® gearbox is ideal for our application because, even with its compact size, it can withstand the high torques and accelerations involved in the levering process.”

“Ready-made linear units with rack and pinion gears are not only less expensive than a customized solution, but also more reliable and durable. Especially when – as in our case – combination movements of high and lateral travel are involved.”

“The most important thing for us was the high accuracy of the rack and pinion system.”

“We have not found this combination of drive and guide, which also allows several gears to be shifted in succession, anywhere else on the market in this compactness.”

Contact us!

leanSYSTEMS – Automation with a SYSTEM

The leanSYSTEMS product division refers to the development and design of partially and functionally ready plants & systems based on our lifgo® and lean SL® gearbox series.

Our motivation:

You provide the ideas – we provide the implementation!

At leanSYSTEMS, we provide you with the complete know-how and implementation power of our design engineers. We accompany your project from the initial enquiry, through the complete design and planning of your system (incl. service life calculation), right up to implementation on your premises.

Discover:

Lifting Tables Lifting Columns Flexible Positioning Systems Pick & Place & more possibilities

adapted to your needs!

Benefit from the many years of experience of our team of engineers, who are on hand to advise you in the areas of development and design. leanSYSTEMS stands for customised solutions that are designed especially for you, so that they are precisely tailored to your needs.

Our sales team will be happy to advise you!

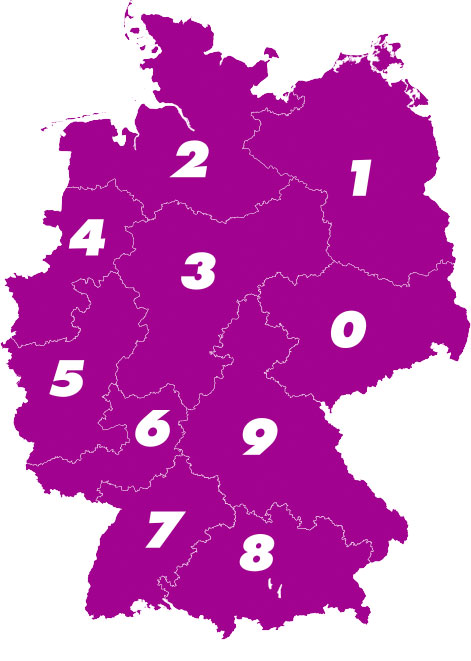

Our sales staff are at your disposal at any time for a non-binding consultation at your premises. To get in touch with your contact person, take a look at who is responsible in your postcode area.

While our product development and design takes place in Oberhausen, our sales staff is at your disposal throughout Germany.

Excellent customer care is part of our understanding of service.

You can find your suitable contact person here:

Head of Sales

Field Service

Sales Manager (international)

ANDREAS SPRENGER

E-Mail: sprenger@leantechnik.com

Phone: +49 208 495 25 65

Mobile: +49 151 57 123 640

MORITZ KNUPLESCH

E-Mail: knuplesch@leantechnik.com

Phone: +49 208 495 25 60

Mobile: +49 151 160 425 84

Key Account Management

Global Key Account Manager

JULIAN BAUKNECHT

E-Mail: bauknecht@leantechnik.com

Telefon: +49 151 527 819 26

Global Key Account Manager

FRIEDRICH KLAEGER

E-Mail: klaeger@leantechnik.com

Telefon: +49 151 647 528 89

Inside Sales

ZIP-Area 0 | 1 | 4 | 5

AMNON SCHÜßLER

E-Mail: schuessler@leantechnik.com

Phone: +49 (0)208 495 25 99