Food & Beverage

Industry solutions from LEANTECHNIK

Hygienic, efficient and flexible – LEANTECHNIK solutions for the food industry

Automated movements with maximum process reliability and hygiene – from processing to packaging.

The food industry requires production facilities that meet the highest hygiene standards while offering maximum efficiency. Whether meat, baked goods, dairy products or beverages – precise movements, fast cycle times and absolutely reliable technology are essential everywhere.

LEANTECHNIK supplies rack and pinion drives and system solutions that have been specially developed for these requirements: robust, easy to clean and flexible in application.

Raw material processing

Hygiene, reliability and efficiency are top priorities in food production. LEANTECHNIK lean SL® drives ensure precise and robust movements right from the primary processing stage of meat, dough or dairy products. They enable cost-effective solutions for conveyor, lifting and handling systems and are ideal for hygienically sensitive environments. Thanks to their compact design and low-maintenance mechanics, the systems are easy to integrate and guarantee high plant availability – day after day.

Filling & portioning

In filling and portioning processes, precision determines product quality and cost-effectiveness. With lifgo® hp rack and pinion drives from LEANTECHNIK, movements can be achieved with maximum repeat accuracy and speed – ideal for dosing systems, cutting systems or high-performance filling lines. The robust mechanics ensure consistent performance even in 24/7 operation, while the backlash-free guidance enables µ-precise positioning. This results in reliable, efficient systems for maximum output and consistent product quality.

Packaging

Whether carton packers, tray packers or tubular bag machines – fast format changes and flexible motion sequences are crucial in food packaging. With LEANTECHNIK’s DAP 3-axis positioning systems and lift tables, packaging lines can be designed precisely and ergonomically. The systems enable exact, repeatable movements at high cycle speeds and support safe, efficient handling of different packaging sizes. The result: maximum flexibility, short changeover times and stable processes – from primary to end-of-line packaging.

Palletising & Logistics

In food production, products must be handled safely, hygienically and efficiently at the end of the line. LEANTECHNIK lifting columns and transfer systems enable precise palletising, picking and transport processes – even with high volumes and heavy loads. Thanks to their modular design, the systems can be integrated in a space-saving manner and flexibly expanded, for example for direct transfer to the automated warehouse. This creates a continuous material flow with high process speed and maximum operational reliability – from packaging to logistics.

Good reasons for LEANTECHNIK as a partner in Food & Beverage

32

YEARS

INDUSTRY EXPERTISE

Modular construction kit

Short delivery times

Component & Complete System

Internationally proven

Certified according to:

Case Study

Food industry

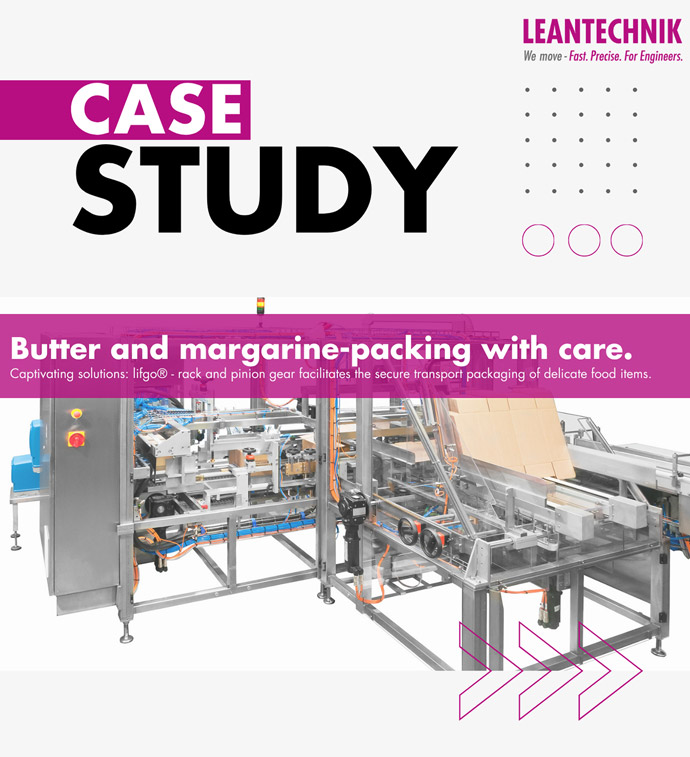

Wrap-around-Tray-Packer

Reliable movement in step with the food industry

When packaging sensitive foods such as butter or margarine, precise and dynamic movements are essential. In the tray/wrap-around packer from Schäfer & Flottmann, a lifgo® 5.1 linear rack and pinion gear from LEANTECHNIK performs the lifting movement for the cardboard blanks. Thanks to its compact design and integrated guide, the gear can be integrated in a space-saving manner – and meets the requirements for speed, repeat accuracy and load capacity in 3-shift operation.

Frequently asked questions

Are LEANTECHNIK systems food-safe?

Yes, we offer variants with food-grade lubricants and stainless steel components.

Technical: NSF-H1 certified lubricants, corrosion-resistant racks and enclosed guides.

How easy is it to clean the systems?

Very simple – all surfaces are smooth, rounded and easily accessible.

Technical: Hygienic design with minimal dead spaces and optional drainage concept.

Can the systems be operated in damp areas?

Yes, all components are splash-proof and corrosion-resistant.

Technical: IP65+ seals and stainless steel housing prevent moisture ingress.

How is downtime minimised through maintenance?

Thanks to durable, low-maintenance mechanics.

Technical: Roller guides and racks are designed for millions of cycles – relubrication only necessary at intervals.

Get in touch to our Experts

Contact form

Address

LEANTECHNIK AG

Im Lipperfeld 7c

46047 Oberhausen

info@leantechnik.com

Phone

+49 (0)208 495 25 0